- Utility and General System Notes

- Heating and Air Conditioning

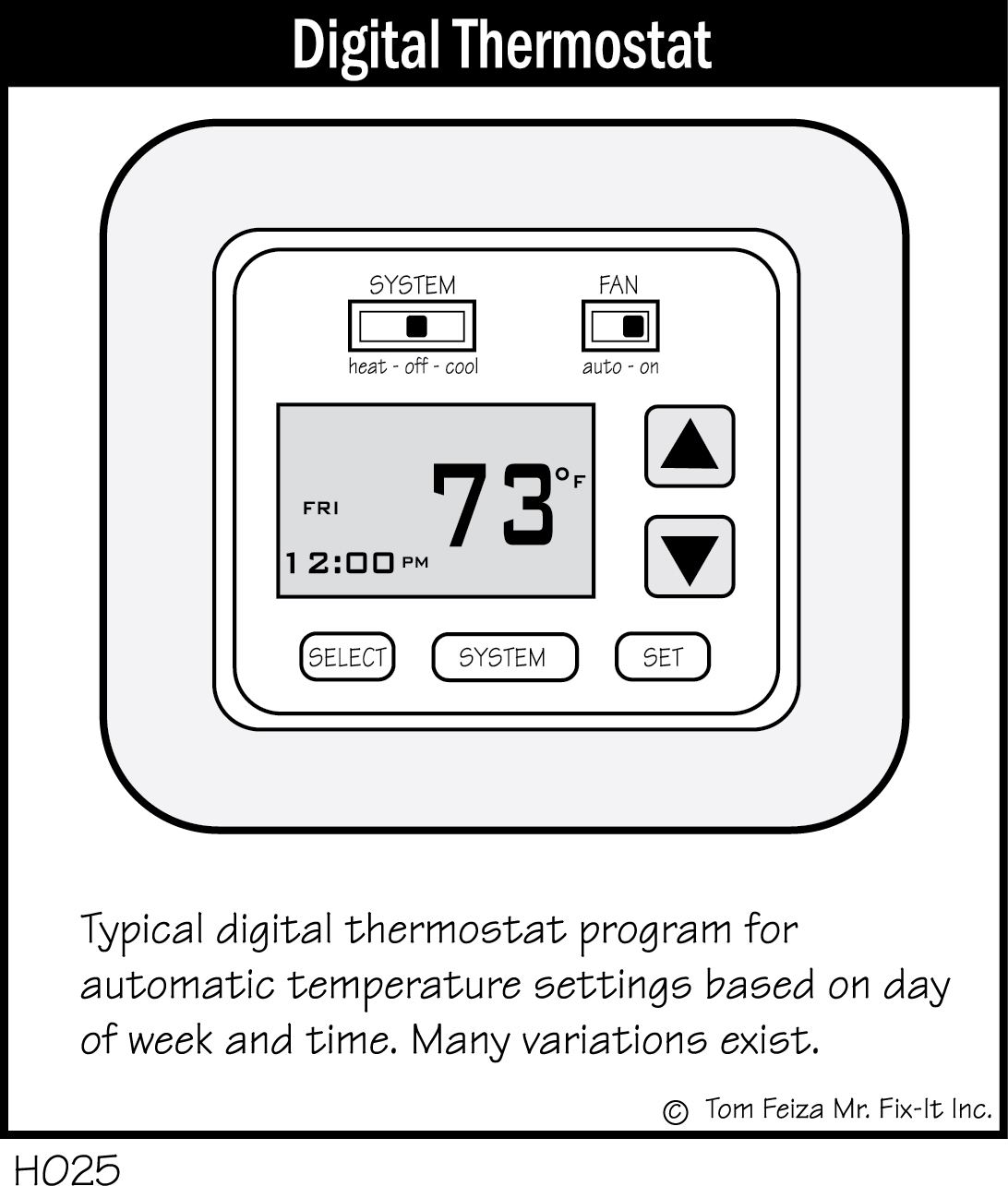

- Thermostat

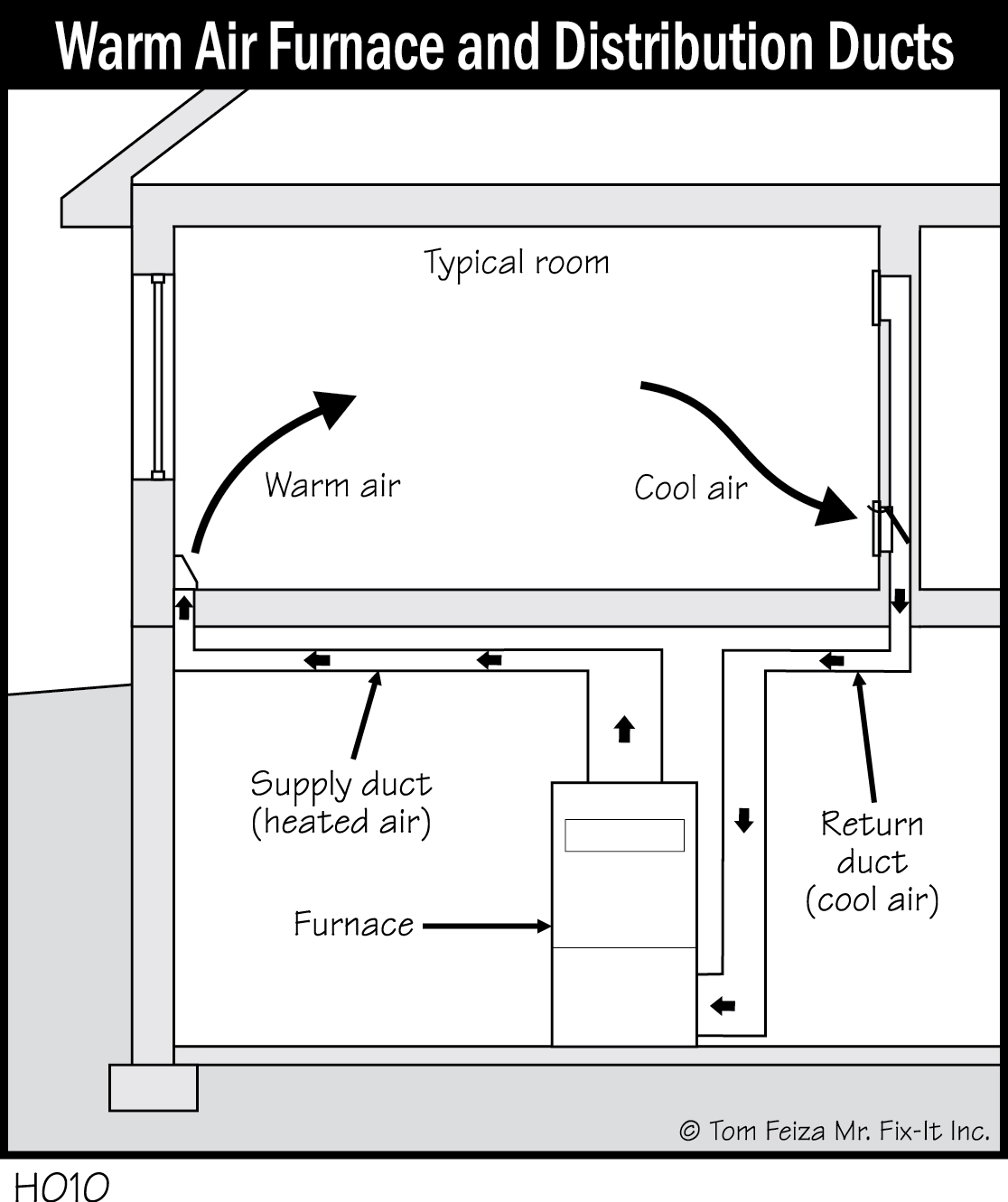

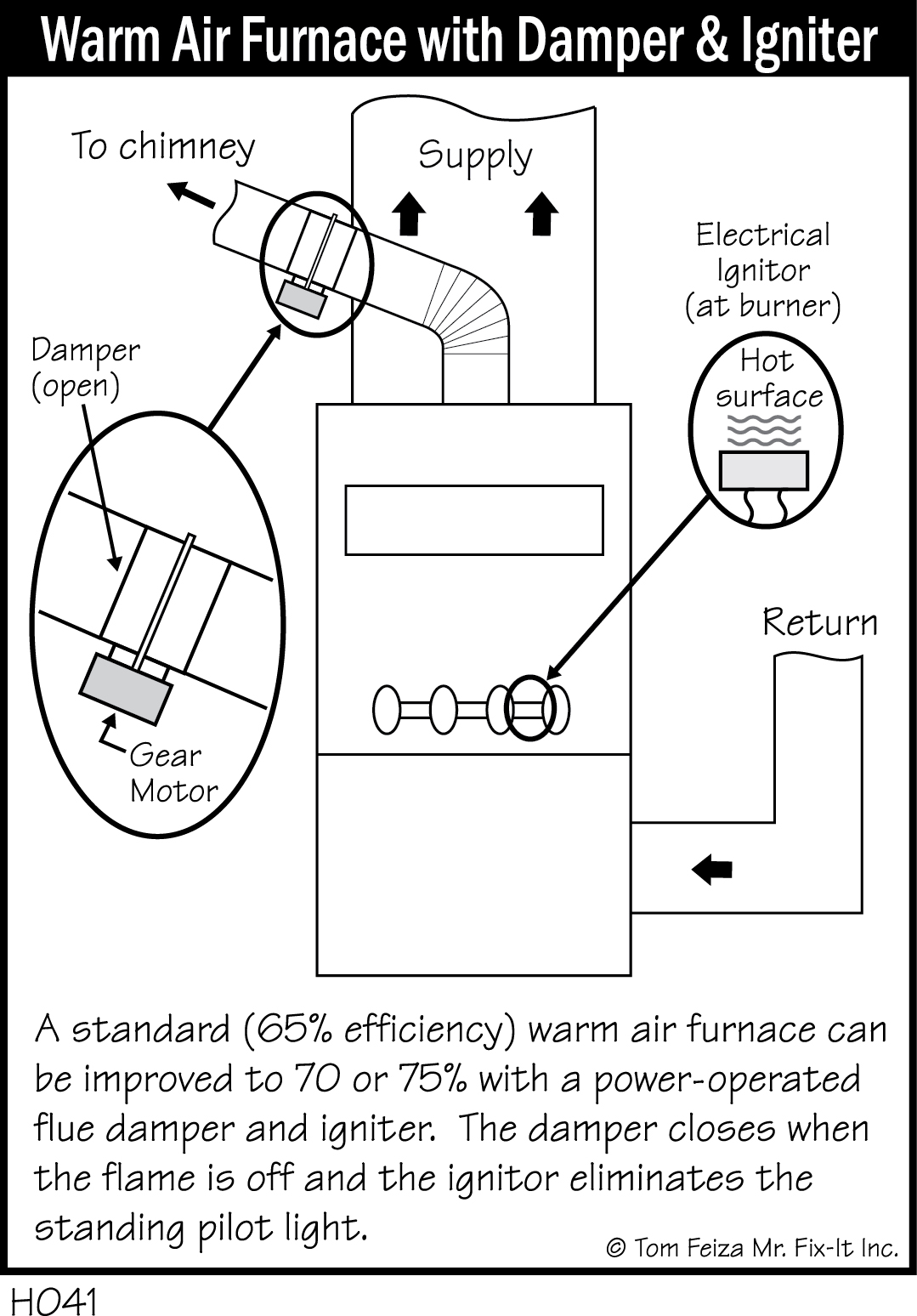

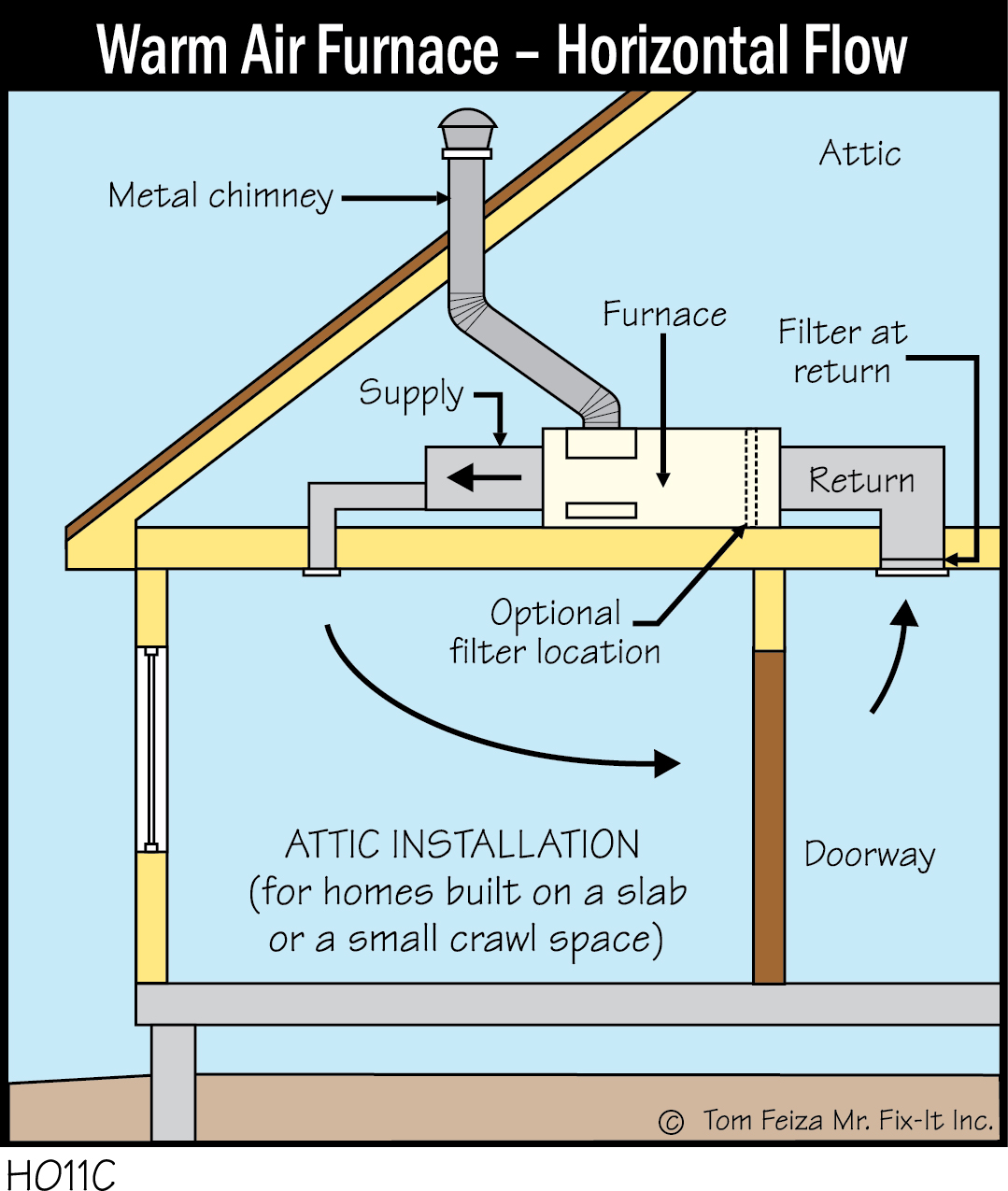

- Warm Air Furnace

- Air Filters

- Hydronic (Hot Water) Heat

- Steam Heating

- Oil Burner

- Central Air Conditioning

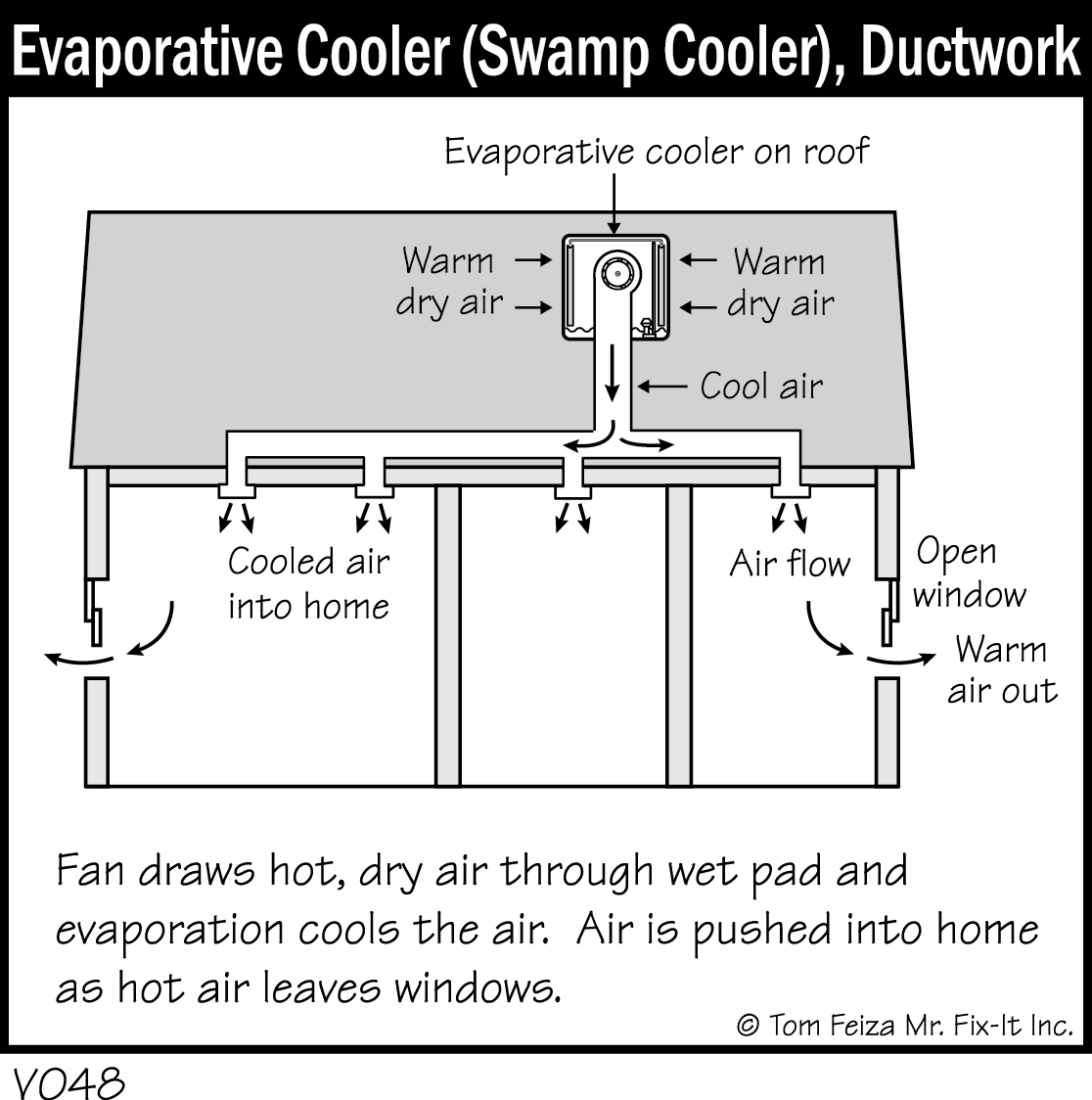

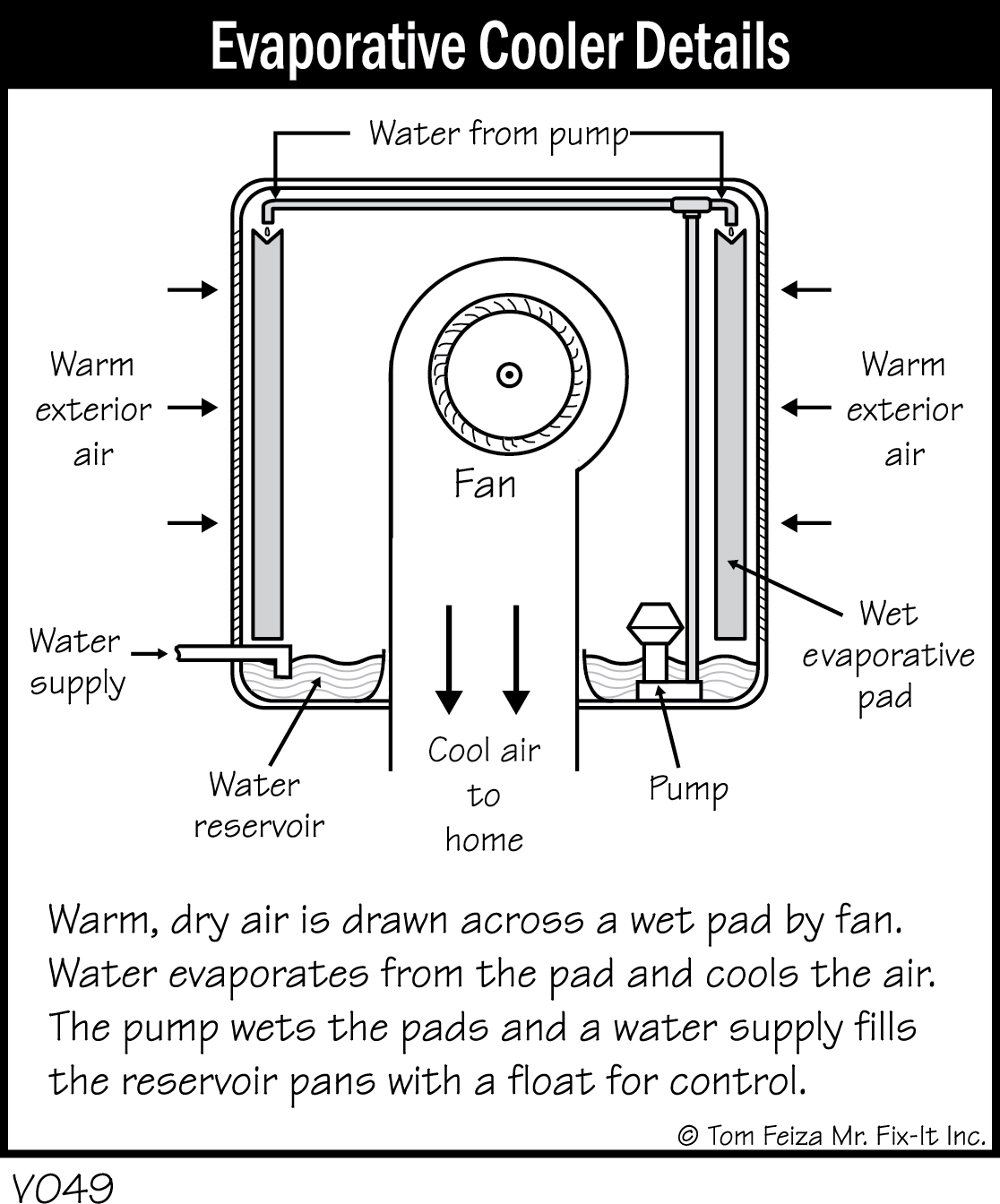

- Central Air Cooling – Evaporative Cooler

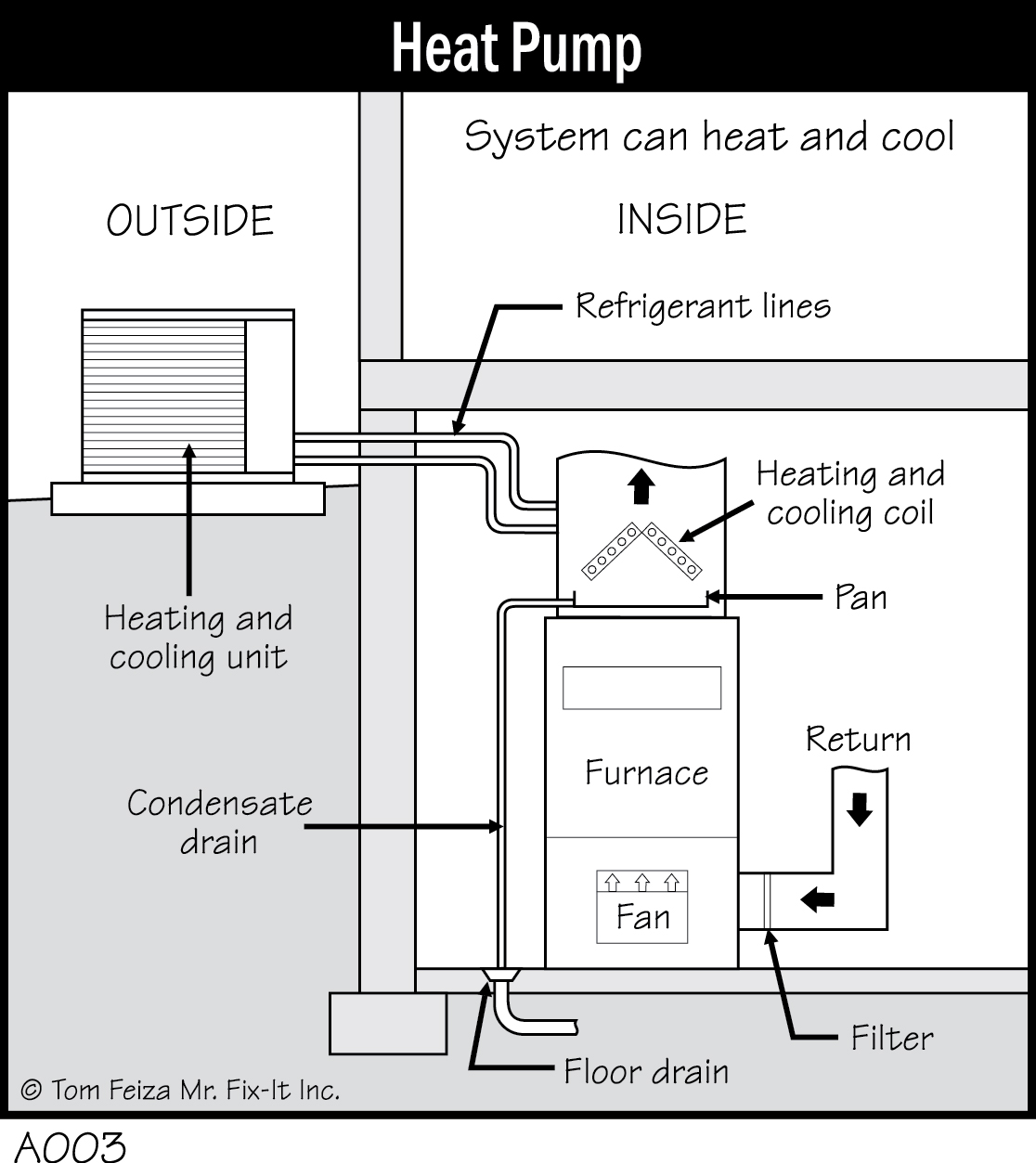

- Heat Pumps

- Heating and Cooling Distribution: Ducts and Dampers

Utility and General System Notes

This is where your homework starts. Take time to read these chapters. They contain important information about the many systems in your home. The explanation of each system includes operating information, terminology, sketches, main shutoffs, and part names.

Since some systems are very complicated, they need to be serviced routinely by contractors. You can do simple maintenance yourself; this information is provided in utility systems sections on Service Requirements by the Calendar.

Your home will not have all of the systems shown in this book. For instance, you may have a warm air furnace or a hot water furnace, but not both. You may have either a central air conditioner or a heat pump. As you read, walk around your home to determine the type of equipment you have and identify important valves and switches. If some systems or parts are confusing, ask a professional service contractor or a knowledgeable friend to walk you through the system.

The chapters on emergencies will help you solve problems and perhaps avoid a service call. I have attempted to include all common problems.

Heating and Air Conditioning

Most homes are heated with a warm air furnace (also called a forced air furnace) because this type of system provides heating and cooling through the same air distribution ducts. A warm air system requires supply grills in most rooms. Some homes are heated with a hydronic (warm water) system that uses radiators, baseboard (convector) elements, or heating pipes buried in walls or floors.

The energy source for heating can be natural gas, propane, or oil. In warmer climates, electrical resistance heating elements may be used in a warm air furnace. Usually, the energy source for air conditioning is electricity, but gas-powered engine systems can also provide cooling.

Some homes have separate heating and cooling systems. One common system combines hydronic heating with ducted air conditioning.

As you review the information on heating and air conditioning, identify the system used in your home.

As with all systems in your home, you must understand the basics of heating and air conditioning so you can perform basic maintenance and operate the system properly and efficiently.

Must Know / Must Do – Heating and Air Conditioning

- Understand how your heating and cooling system works and who you can call for service.

- Understand the control (thermostat) for the heating and cooling system.

- Perform basic maintenance: filter changes and lubrication.

- Schedule yearly maintenance by a professional.

- Identify and know how to use emergency shutoffs for electricity, gas, oil, and so on.

Thermostat

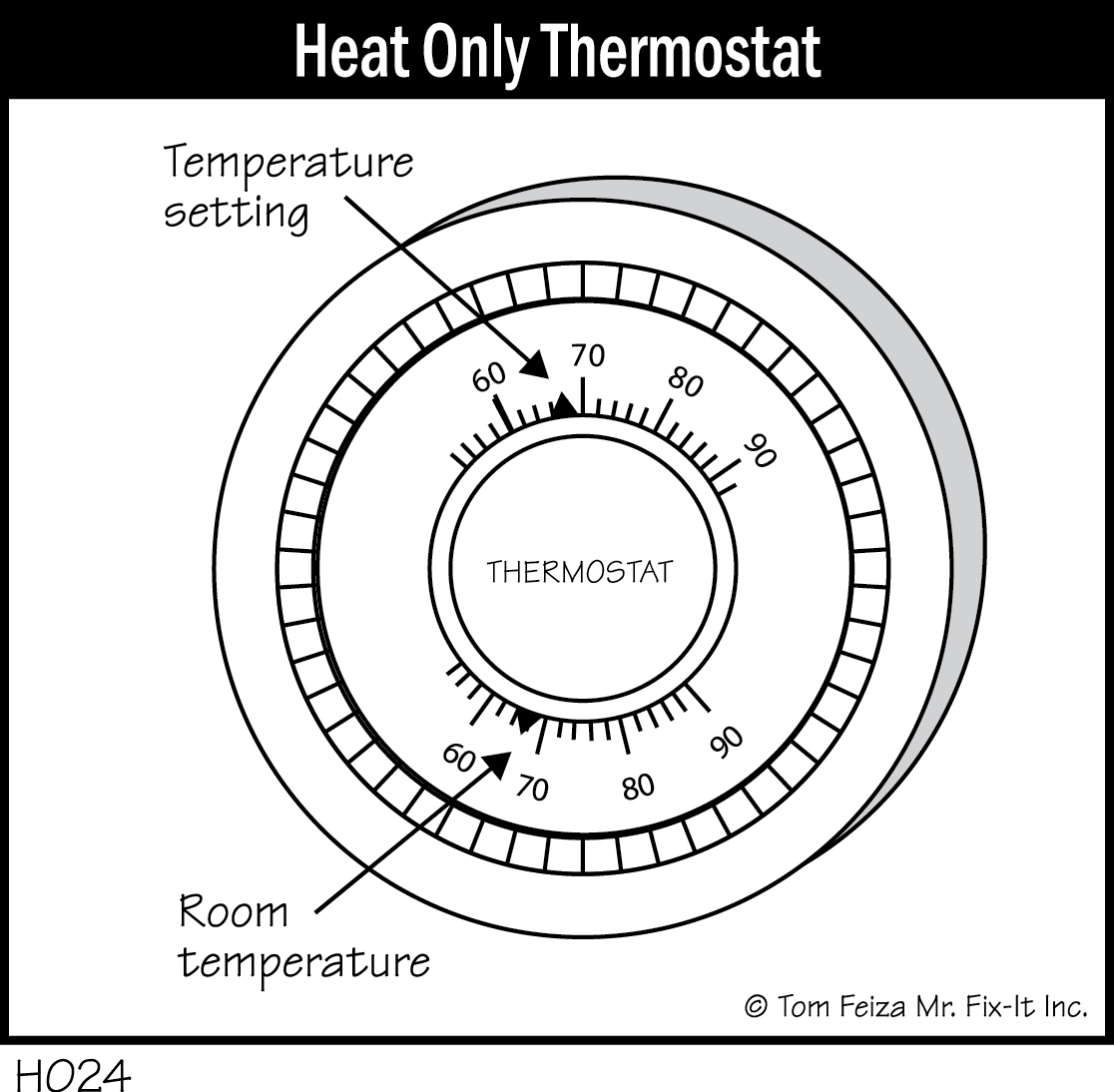

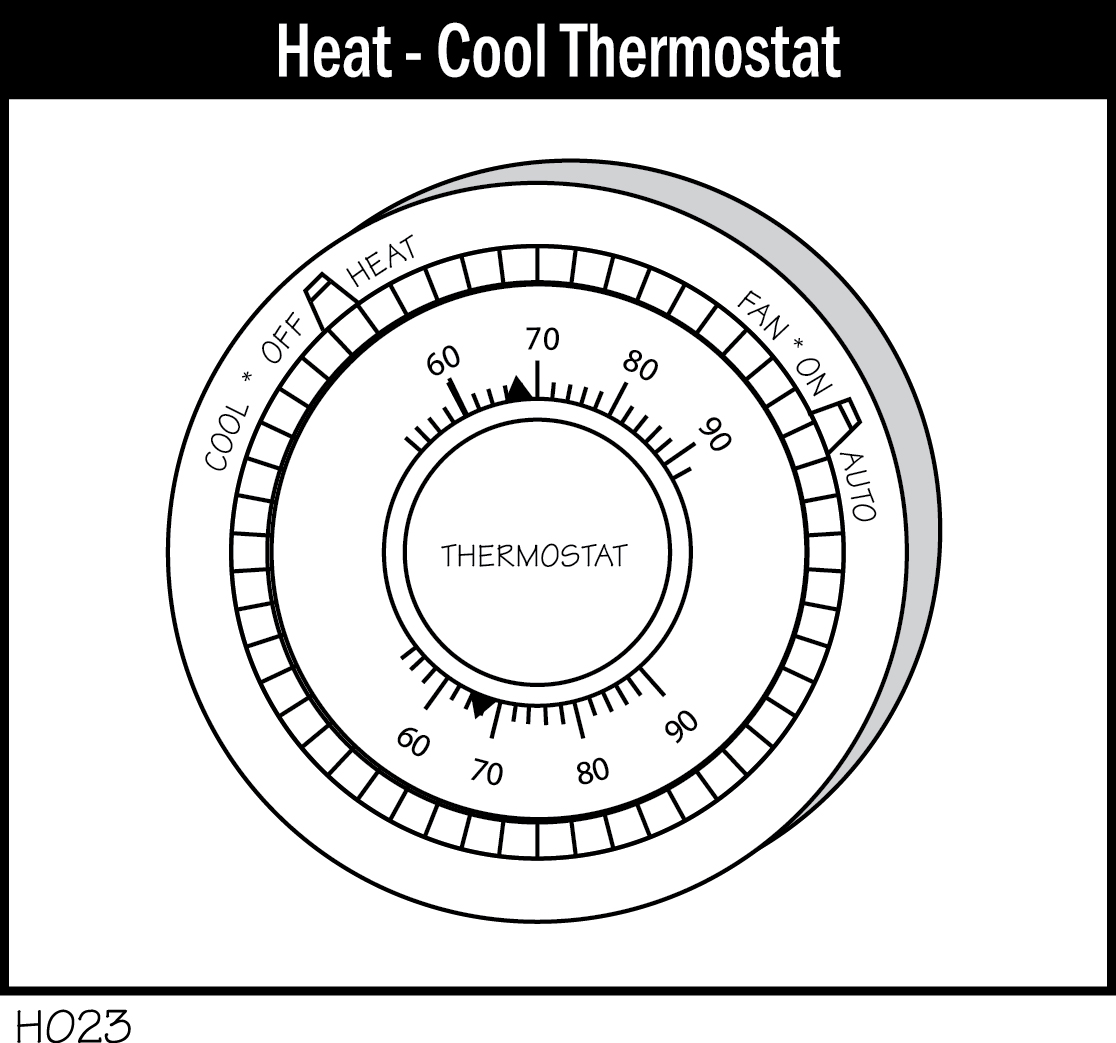

The thermostat provides automatic control for heating and cooling systems. You set it to the temperature you want to maintain. The thermostat, located in the conditioned (heated and/or cooled) space, senses room temperature, and when the room temperature varies from your set-point, the thermostat activates the heating or cooling system.

A dual heating/cooling thermostat will have switches that let you change the system from heating to cooling and operate the fan separately. Some thermostats also allow you to turn off the heating and cooling systems.

All heating and cooling thermostats operate with similar buttons and controls. The basic and common controls are as follows:

HEAT – OFF – COOL

This switch will put the system in the heating mode (HEAT), turn the system off (OFF), or switch the system to cooling (COOL) if there is an air conditioning system. Once the system is set to HEAT or COOL, the thermostat temperature setting controls the system based on the room temperature.

FAN – ON – AUTO

This switch allows operation of the fan manually (ON), independent of the heating and cooling system. This allows you to circulate air in your home without operating the heating or cooling system. In the automatic (AUTO) setting the fan will cycle on and off as needed by the heating or cooling system. AUTO is the setting normally used.

The typical home system is either fully on or fully off; it doesn’t provide variable heating/cooling. When the thermostat calls for heat, the furnace reacts at 100 percent capacity until the room temperature reaches the setpoint; then the furnace shuts off. Turning the thermostat up higher will not heat the room any faster. When you switch the system to cooling, turning the thermostat lower will not cool the room any faster. (A few homes do have complicated systems in which the furnace is capable of variable heating/cooling, but these are the exception.)

Electronic (or digital) thermostats can be programmed for automatic adjustment of the set-point temperature based on time of day and day of week. These help conserve energy; they can lower the temperature during sleeping hours or when your home is not occupied.

Thermostats should be installed and maintained by professionals. Special anticipator settings on the thermostat match its operation with the operation of the furnace. If you replace a thermostat, make sure that this anticipator setting is done properly.

Thermostats are very sensitive. Your thermostat should be level, out of direct sunlight, and away from direct heat sources. If a thermostat develops a major problem, the usual recommendation is replacement rather than repair, because much better electronic thermostats with modern setback capabilities are readily available at reasonable prices.

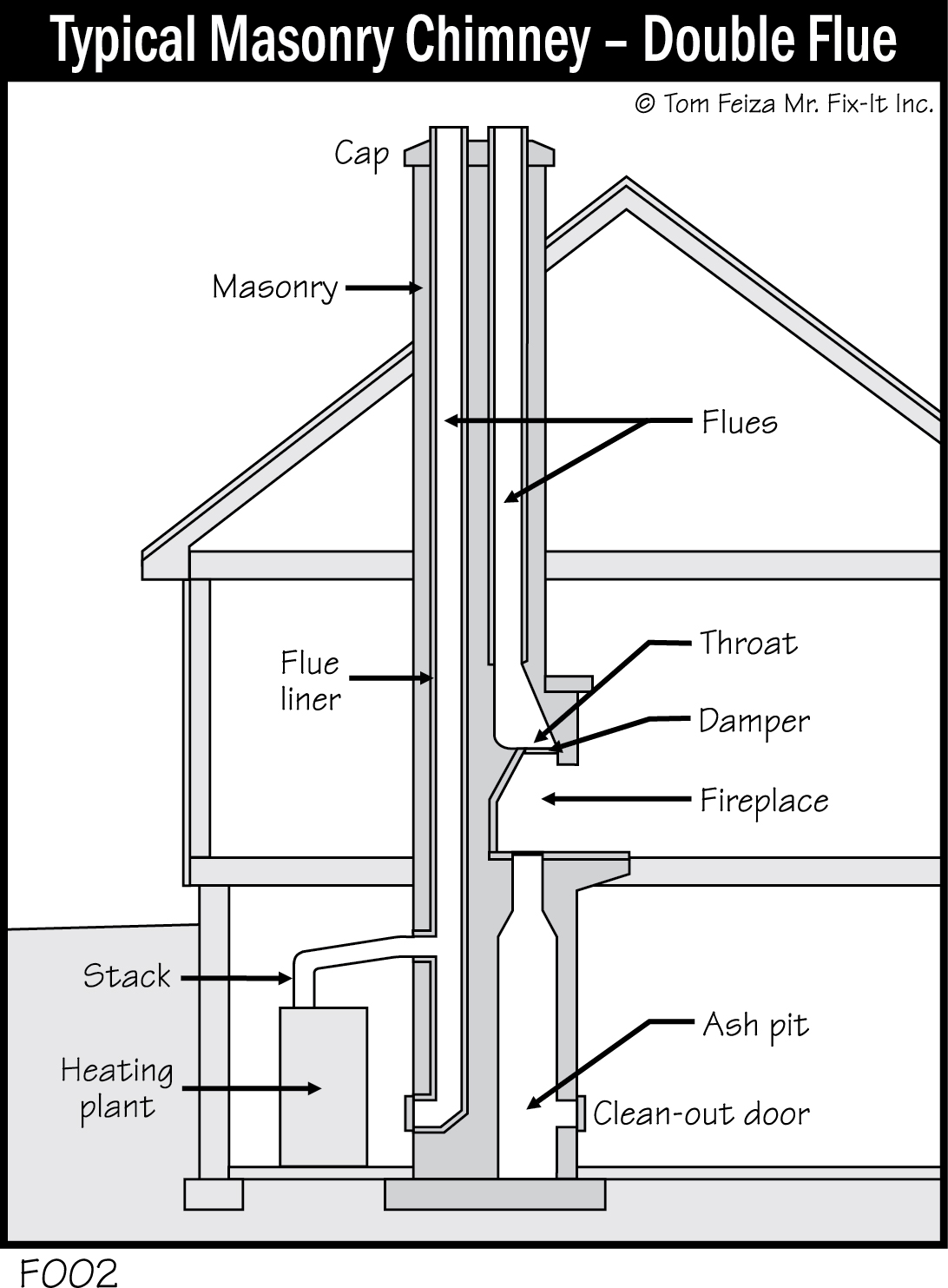

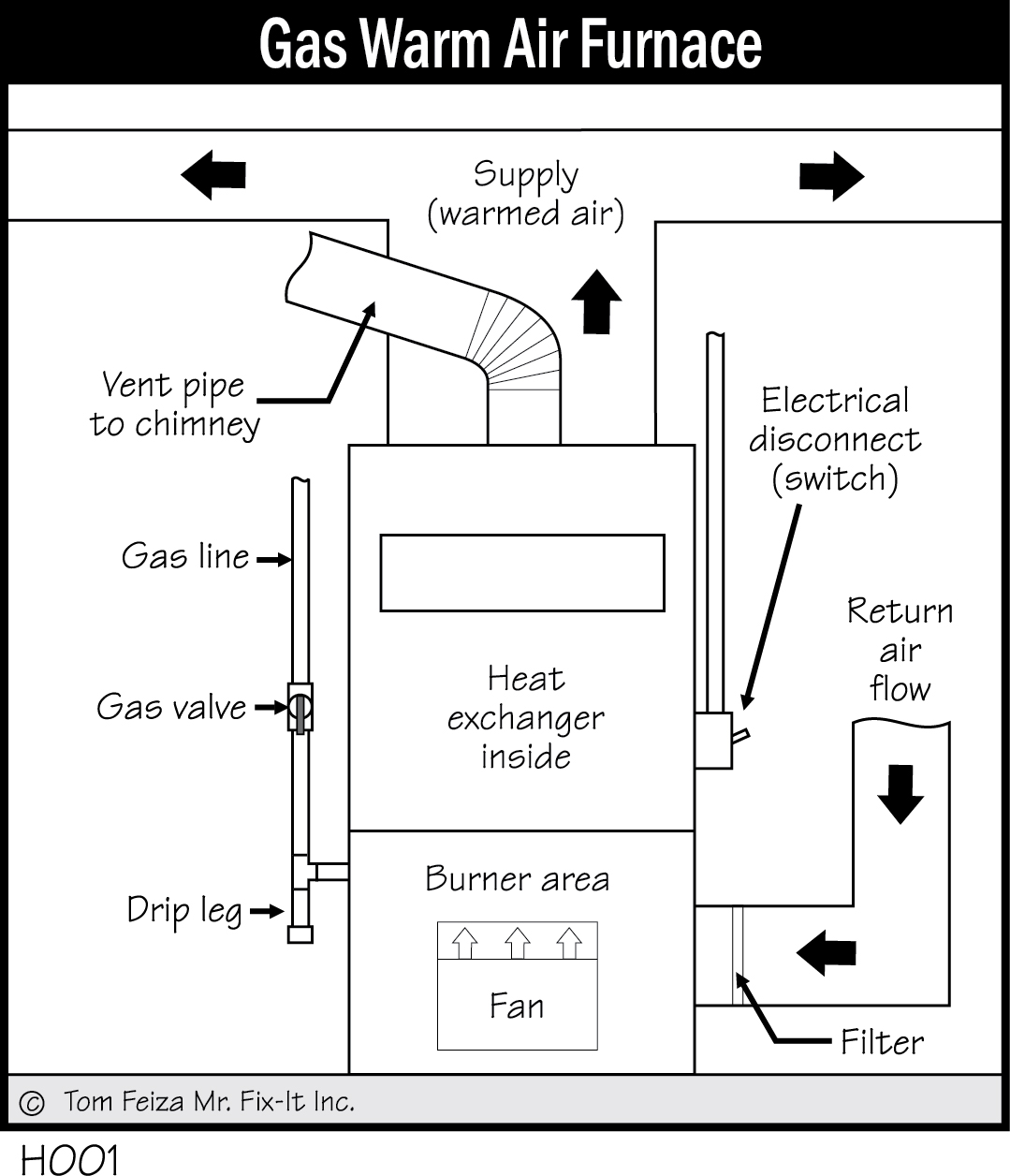

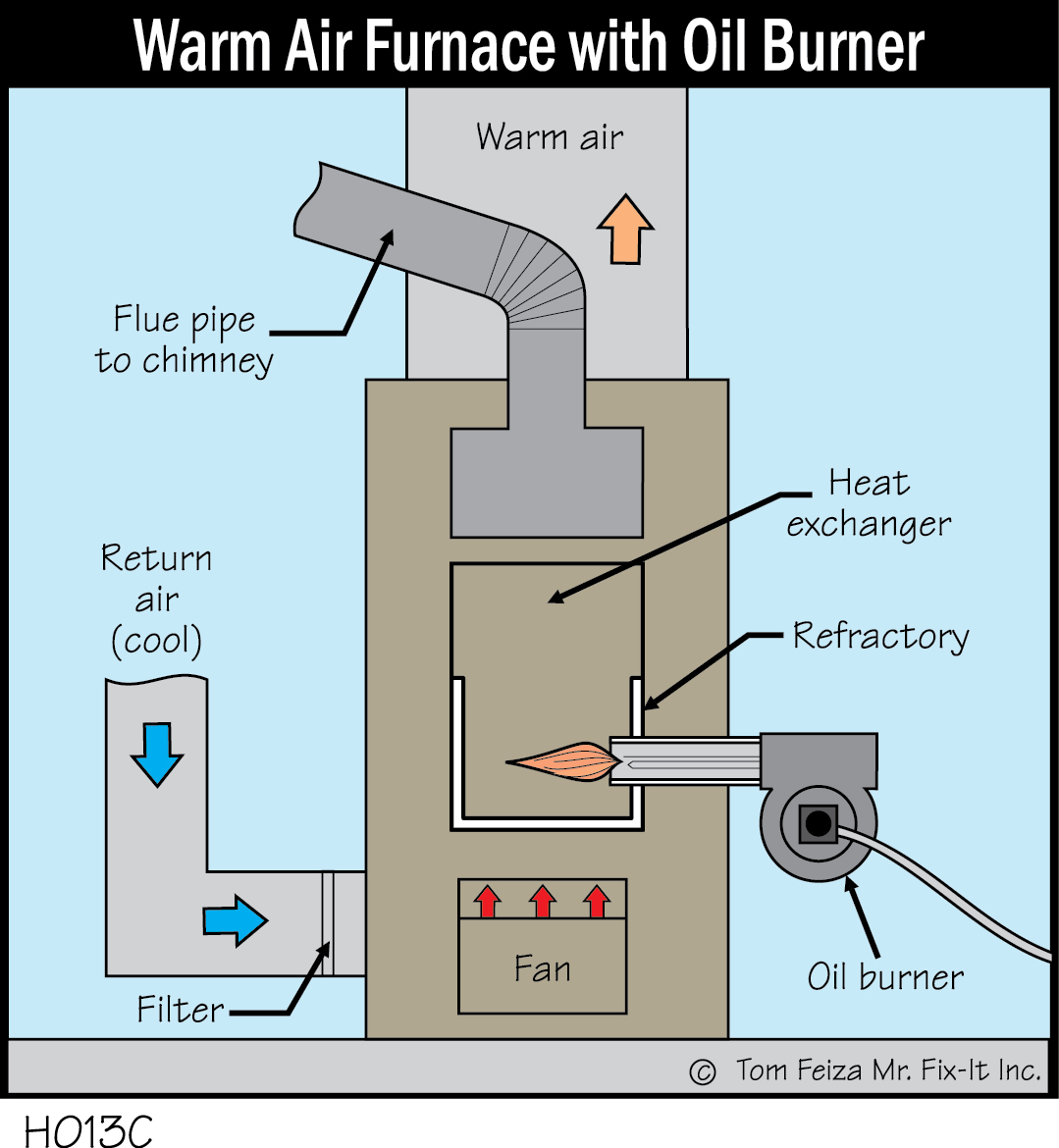

Warm Air Furnace

The most common type of warm air (forced air) furnace provides heat by burning a fossil fuel to warm air and then distributing the warm air inside your home. The heat source is confined within a heat exchanger inside the furnace housing. For gas, propane, and oil systems, the fuel is burned inside or below a heat exchanger. The hot products of combustion flow through the heat exchanger and up a chimney or are drawn out through a vent pipe.

The hot products of combustion warm the metal of the heat exchanger. After a minute or so, when the heat exchanger’s metal is warm, the circulating (furnace) fan starts. This fan circulates air across the hot metal on the outside of the heat exchanger. The heated air warms your home.

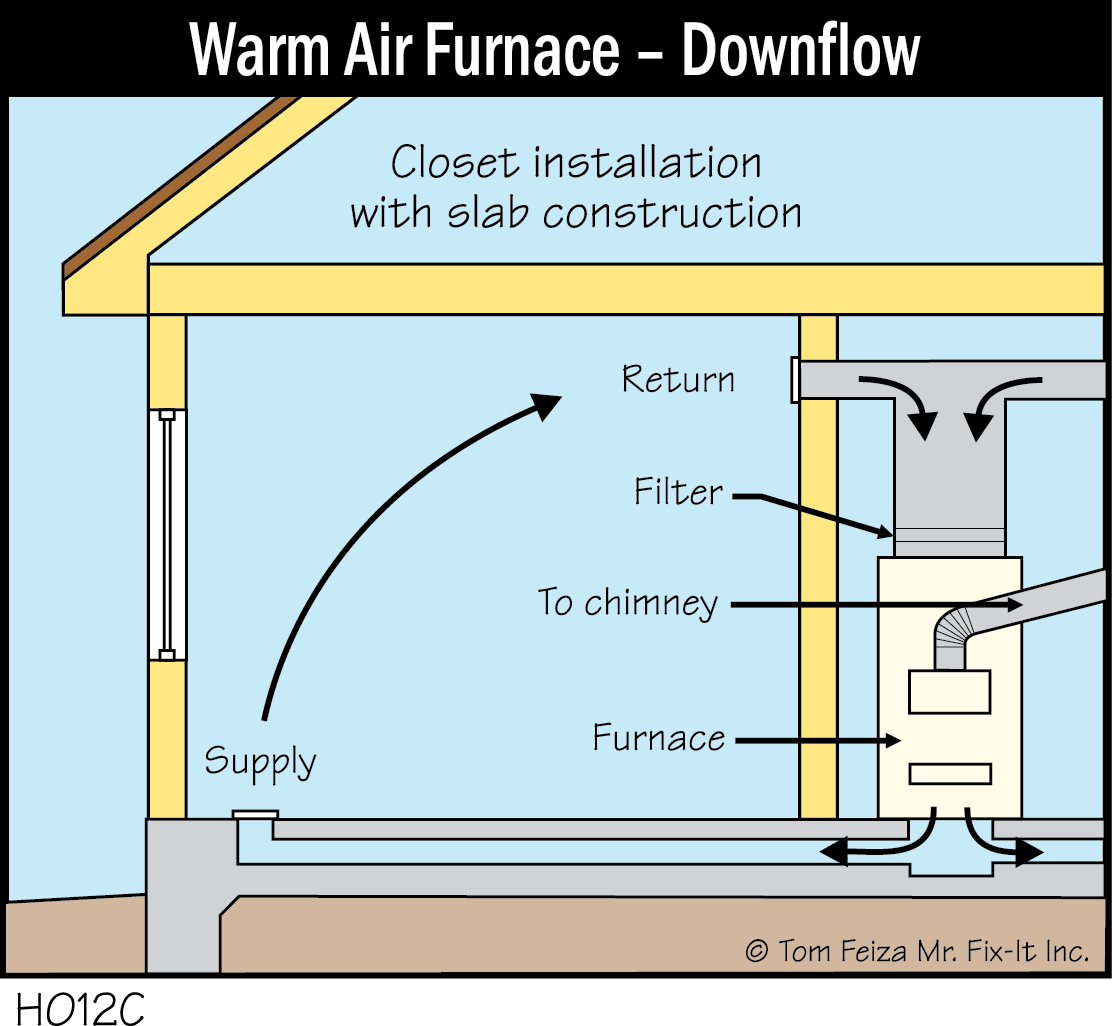

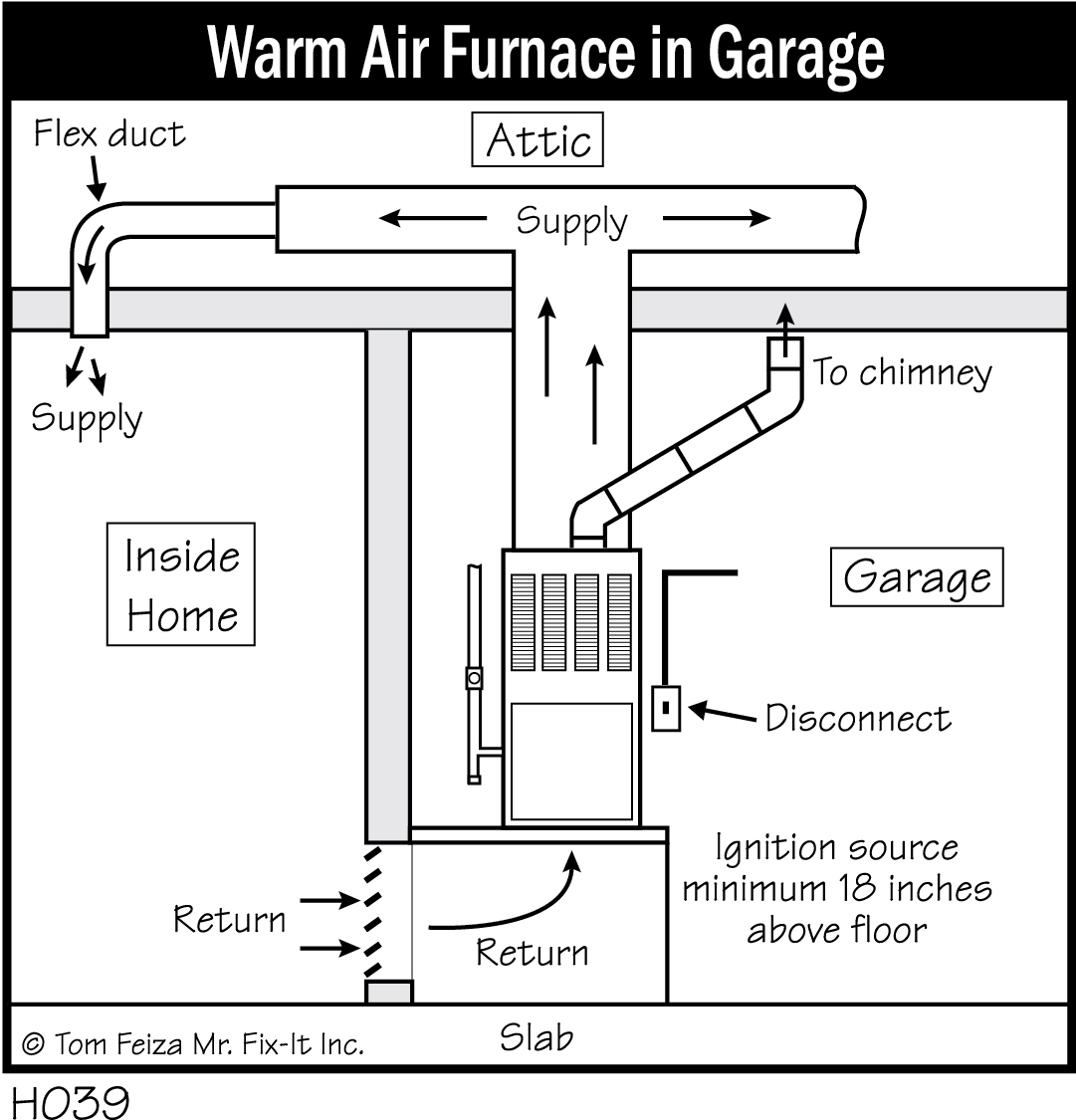

For homes without basements or crawl spaces, warm air furnaces can be located in attics or closet spaces. The typical warm air furnace located in an attic or crawl space uses the same components as a basement (upflow type) furnace, but the furnace is often designed to operate horizontally to save space.

Furnaces for homes built on a concrete slab are located in the attic or in a closet. For the closet installations, a downflow warm air furnace may be used. These furnaces are similar to the upflow furnace, but the components are reversed. The heat supply ducts are in the floor slab. Homes on slabs can also have a warm air furnace in a closet using a typical upflow furance – the supply ducts will be in the attic and the return will be through the halls or in the floor slab.

The efficiency of gas furnaces has improved dramatically in recent years. Standard (60%) warm air furnaces have been improved with electronic ignition devices to eliminate the standing pilot light and prevent this heat loss. These furnaces have also been improved with a motor-operated flue damper in the pipe that goes to the chimney. When the burner is on, the damper is open. When the burner is off, the damper closes and eliminates the draft up the chimney, saving energy. These improvements will make a 60% furnace operate at about 65 to 70% efficiency.

You will find 80% efficiency furnaces that use a draft fan to force the products of combustion up the chimney. You will find 90%+ efficiency furnaces that vent with plastic PVC pipe. These higher efficiency furnaces squeeze so much energy out of the products of combustion that they need special fans to help remove the products of combustion; the combustion gas is not hot enough to naturally draft up the chimney.

In an electric warm air furnace, air circulates directly over an electrical resistance-heating element.

A propane gas furnace is similar to a natural gas furnace but uses a different burner and control system designed for propane.

A warm air furnace recirculates air in your home. It does not draw in outside air unless there are special provisions for an outside air supply (which is not common). The fan circulates the air, which is drawn from the return grills and ducts inside your home and discharged through the supply grills. There will be a furnace air filter located near the fan; you must maintain this filter.

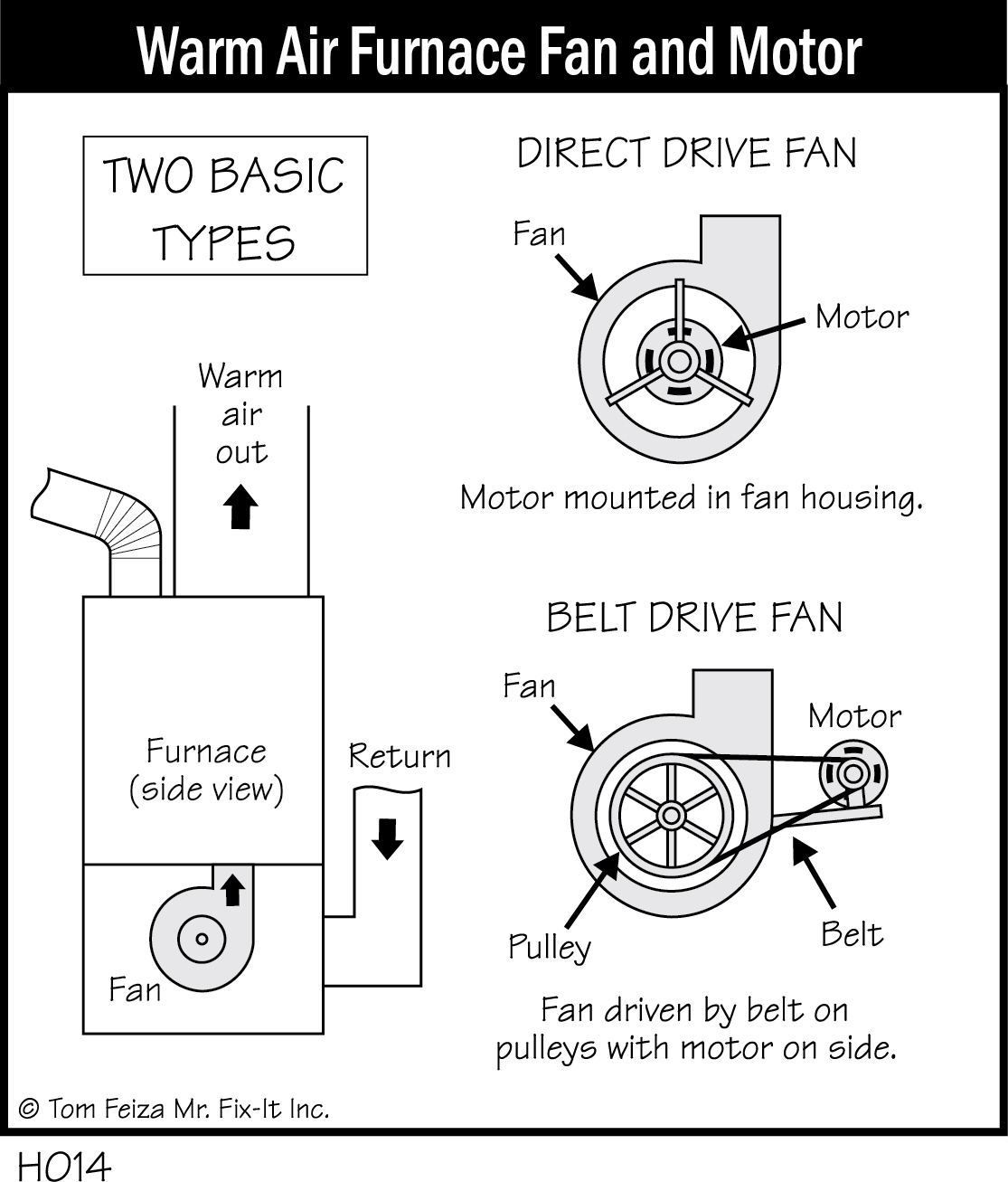

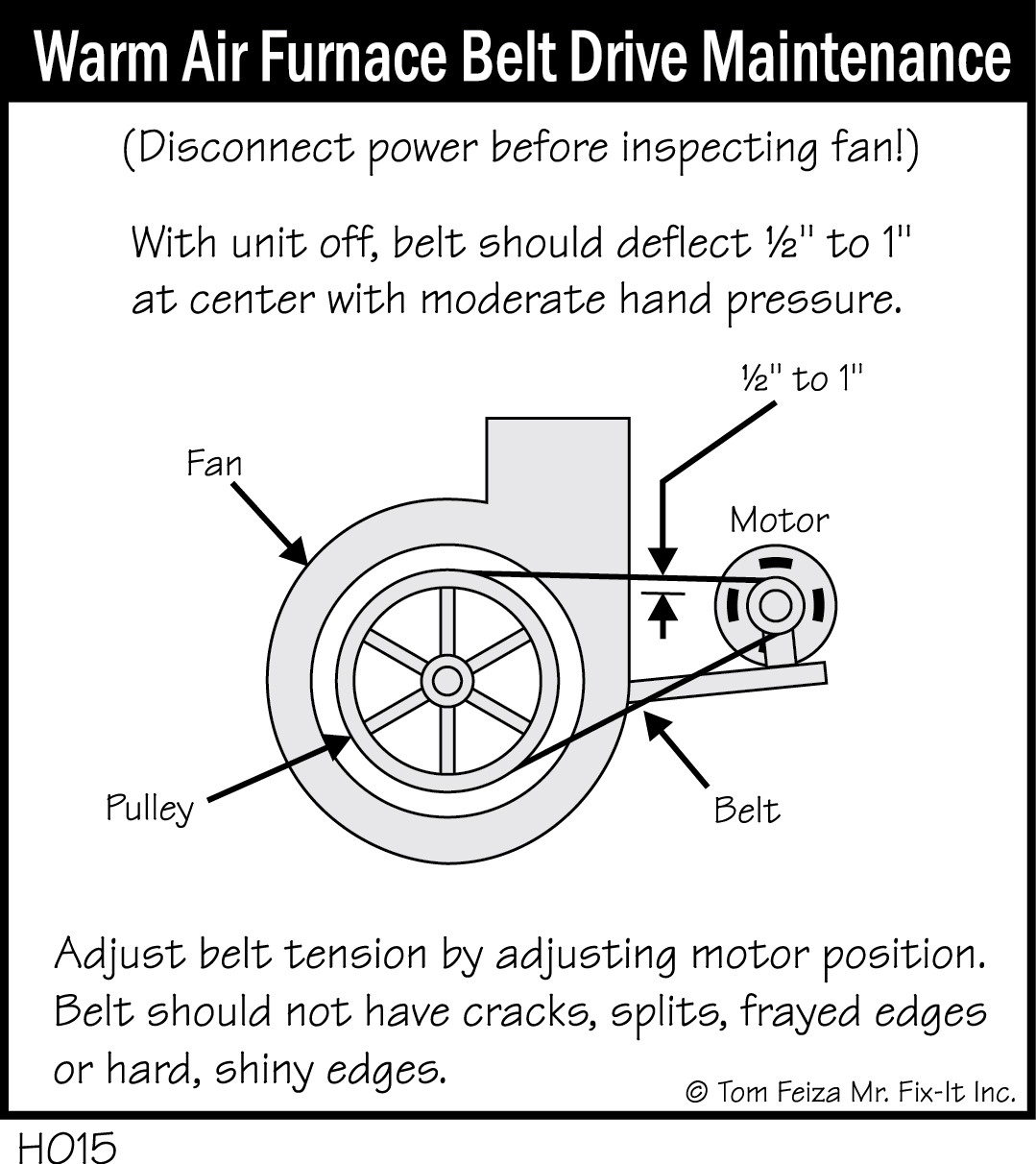

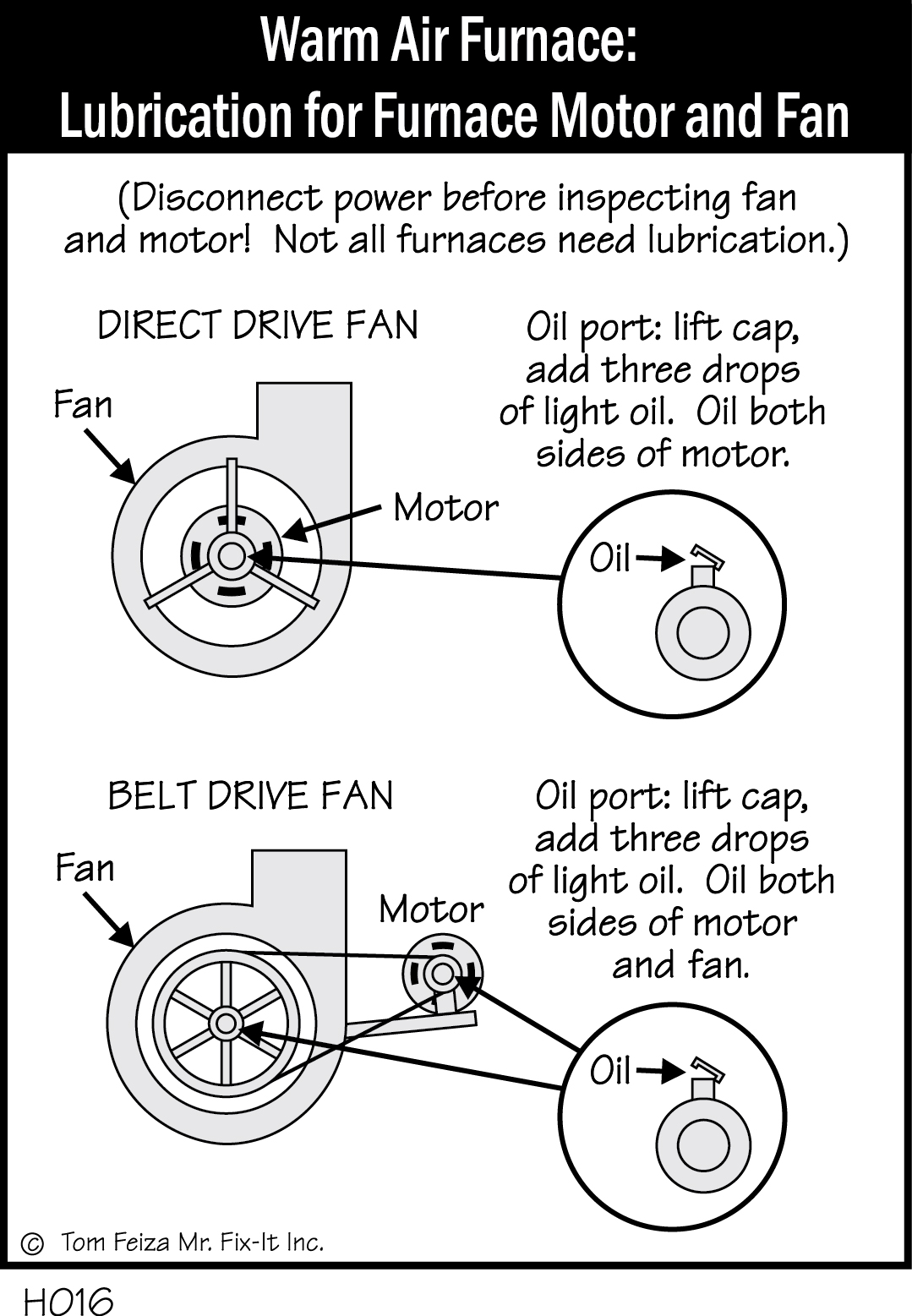

Warm air or forced air furnaces have a circulating fan or blower located near the heat exchanger. This fan circulates the house air over the warm metal of the heat exchanger inside the furnace. The fan may be powered directly by a fan motor mounted inside the fan housing. A motor through a belt and pulley arrangement may also power the fan.

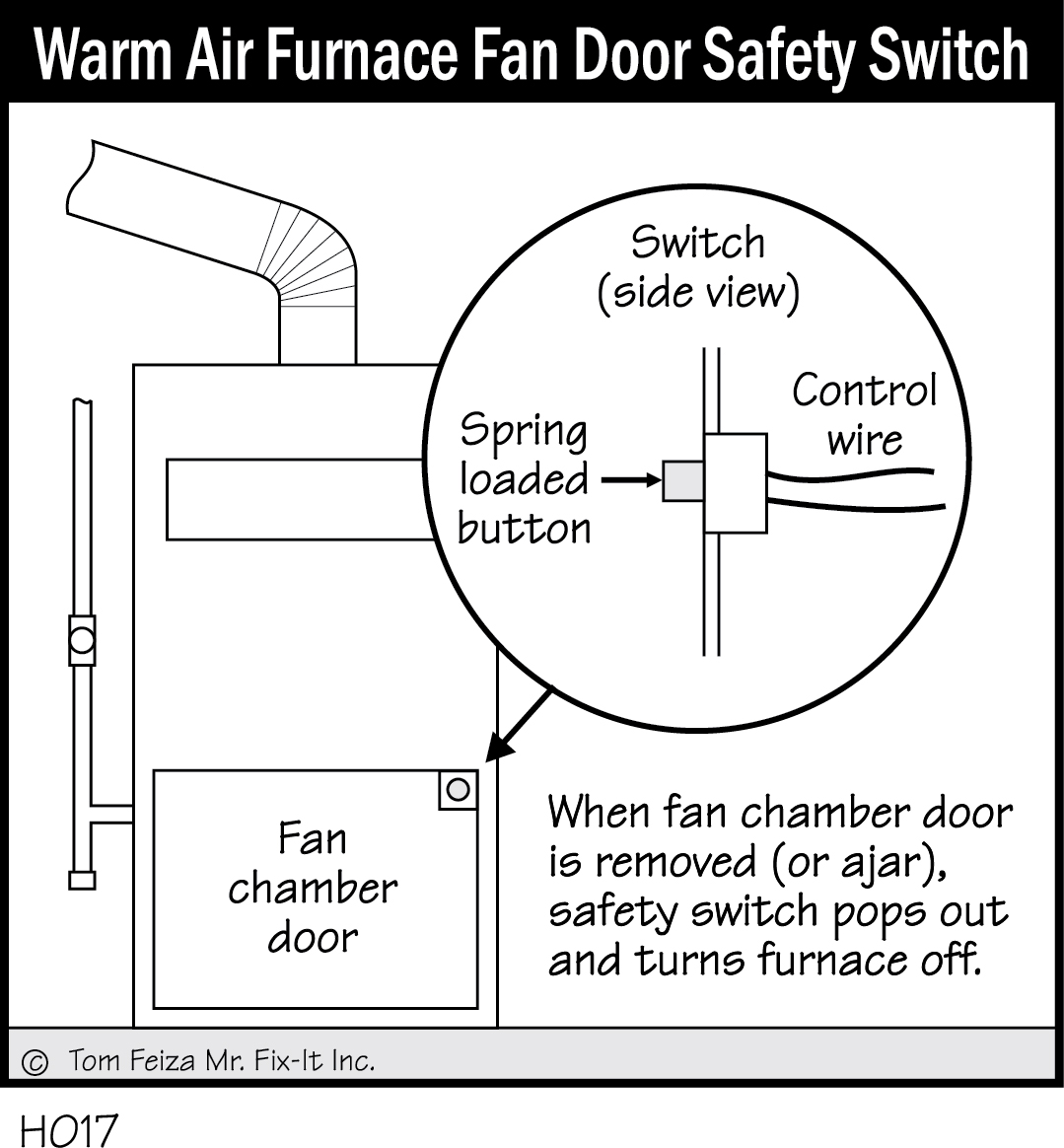

Newer furnaces will also have a safety switch built into the fan access door. When the fan chamber door is removed, this switch shuts the furnace off. This is a safety device that prevents accidental injury from the moving part of the fan system. If you ever have a situation with no heat or no air conditioning, you should check this access door and safety switch. A loose fan access door can inadvertently shut the system down.

With modern systems, heat ducts are located on the floor or ceiling near the outside walls, windows and doors. Returns are placed on interior walls. If the furnace is in the basement or crawl space, supply grills will be near the floor; if the furnace or supply ducting is in the attic, supply grills will be in the ceiling. This modern arrangement provides for good air distribution and greater comfort. Most modern systems have a return grill in every room except the bathrooms.

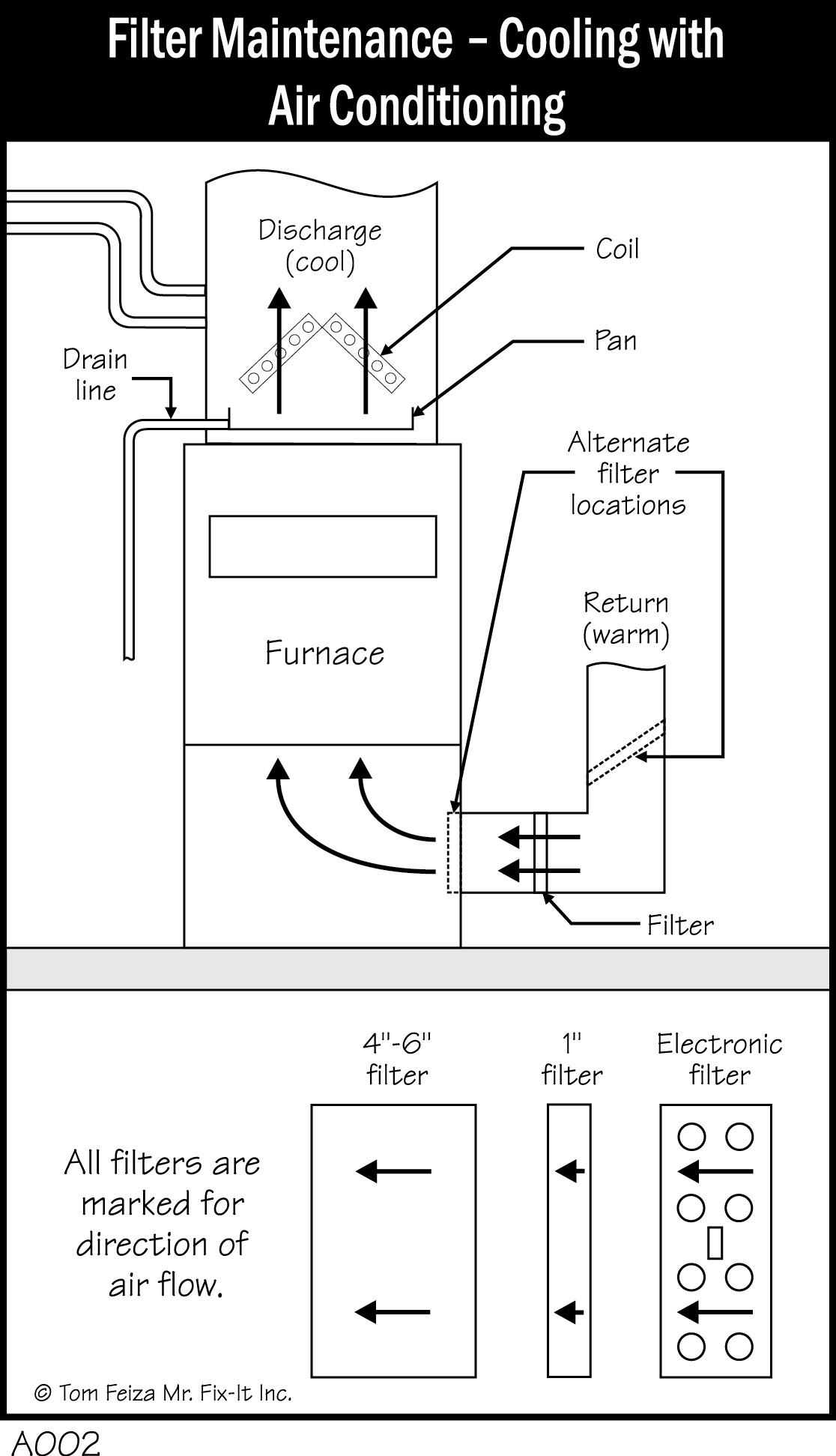

Air Filters

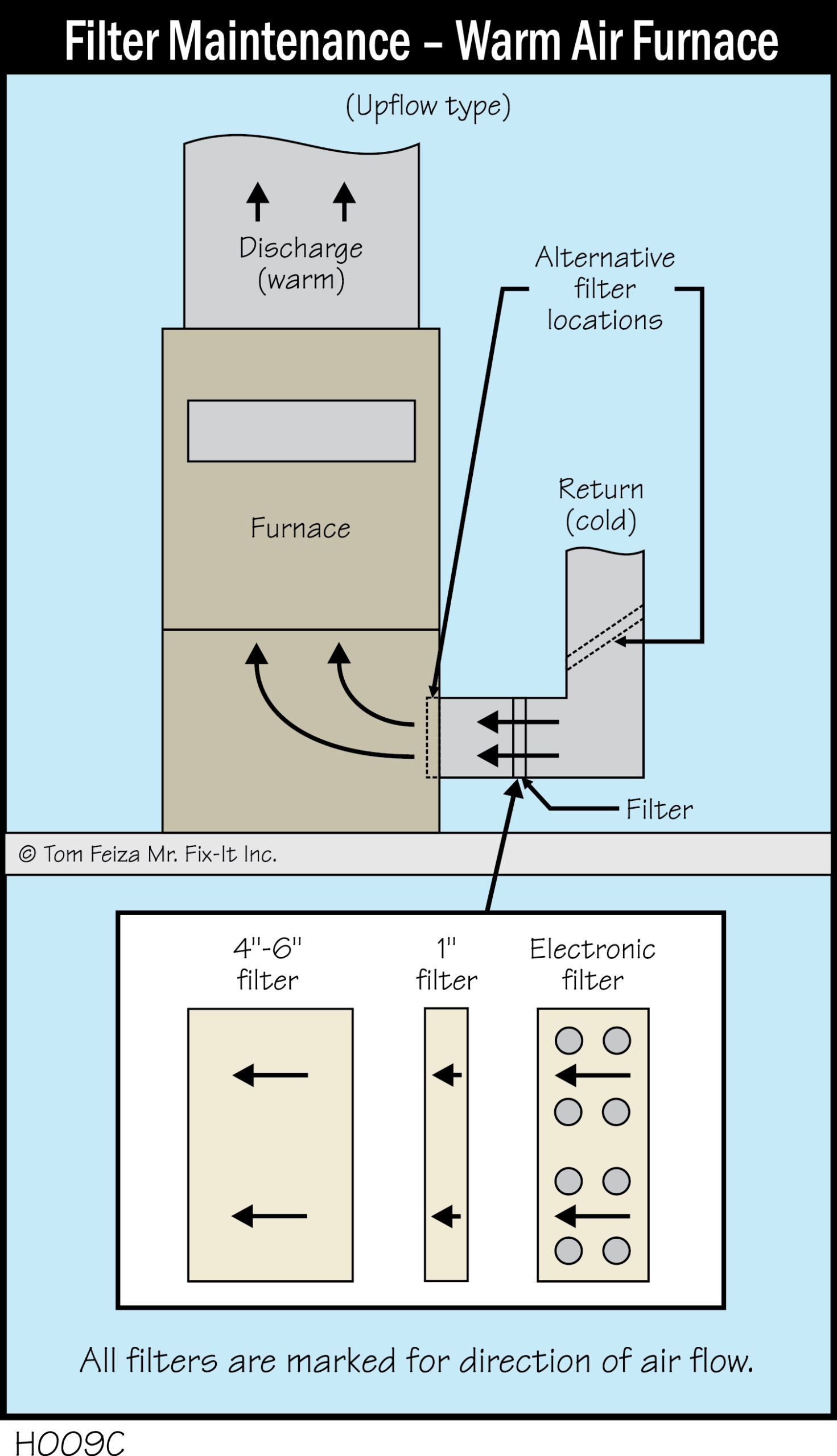

Air filters are provided on all forced air furnaces to remove dirt and lint from heated air.

This keeps the fan, heat exchanger and air conditioning coil clean. It also helps clean the air of your home as air circulates through the system (note the direction of the air flow).

Media Filters

ONE-INCH-THICK FIBERGLASS

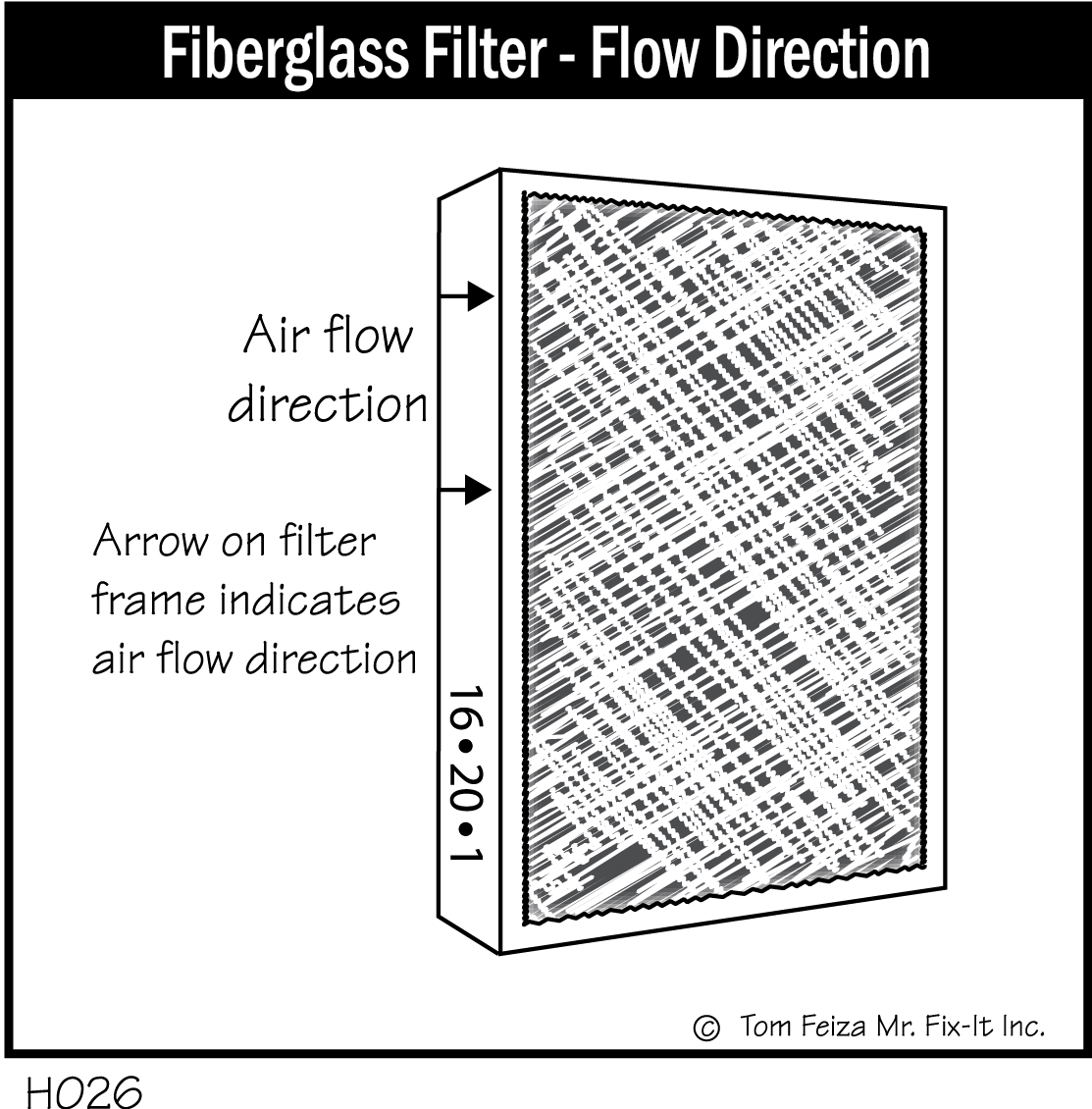

The standard filter on most furnaces is a nominal 1”-thick media filter. Usually, this filter is made of fiberglass. The filter should be changed when it is visibly dirty—usually every month or two, depending on the quality of the filter and the amount of dirt in your home’s air. Children, pets, plants, and activity tend to produce more dirt that finds its way into the heating system.

Be careful about the direction of the air flow through the filter. Filters are designed to be installed with one particular side facing the air stream. Most filters have directions or an arrow telling you which side should be installed toward the furnace. The arrow is the direction of the air flow and should be toward the base or the fan of the furnace.

Must Know / Must Do – Routinely Maintain the Furnace Filter

Maintenance is based on the type of filter, how often the unit is running (heating and cooling), and how you use your home. The three basic types of filters are media, electronic, and electrostatic.

Remember: the furnace filter is also used when you operate the fan and/or central air conditioning, so you should check on the filter during the summer, too.

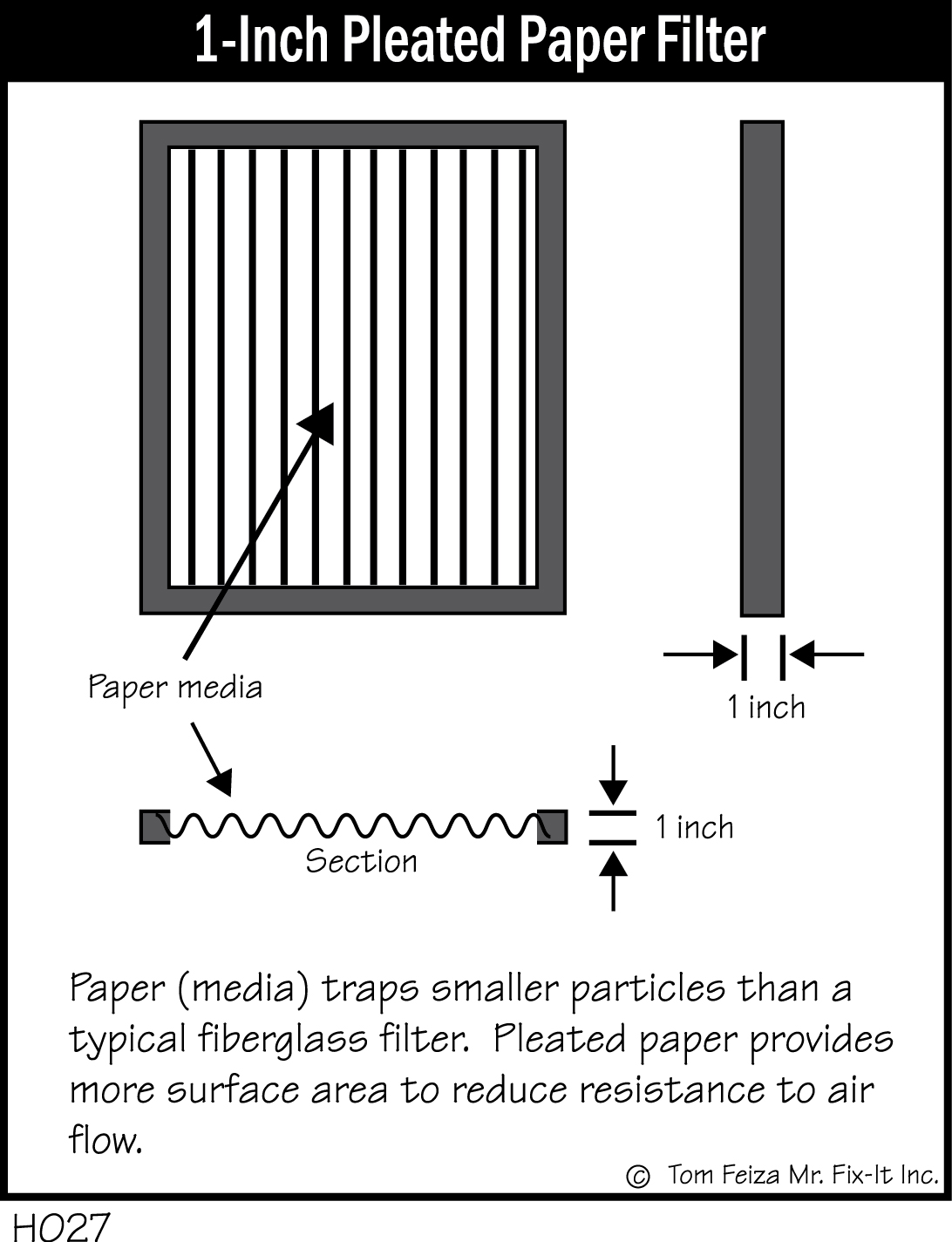

PAPER

I recommend that you try one of the pleated paper filters. These catch more dirt than inexpensive fiberglass filters. Some even have a static charge to attract dirt. Others have a carbon filter content. Paper filters cost between $3 and $15 and can be found in most hardware stores. You will need to change this type of filter more often because it collects more dirt.

WASHABLE

Washable filters can be made of foam or woven synthetic fiber. They are about as effective as inexpensive fiberglass filters. You can improve the efficiency of a foam filter by spraying it with a special filter coating; this oily/waxy spray helps the filter hold dirt better.

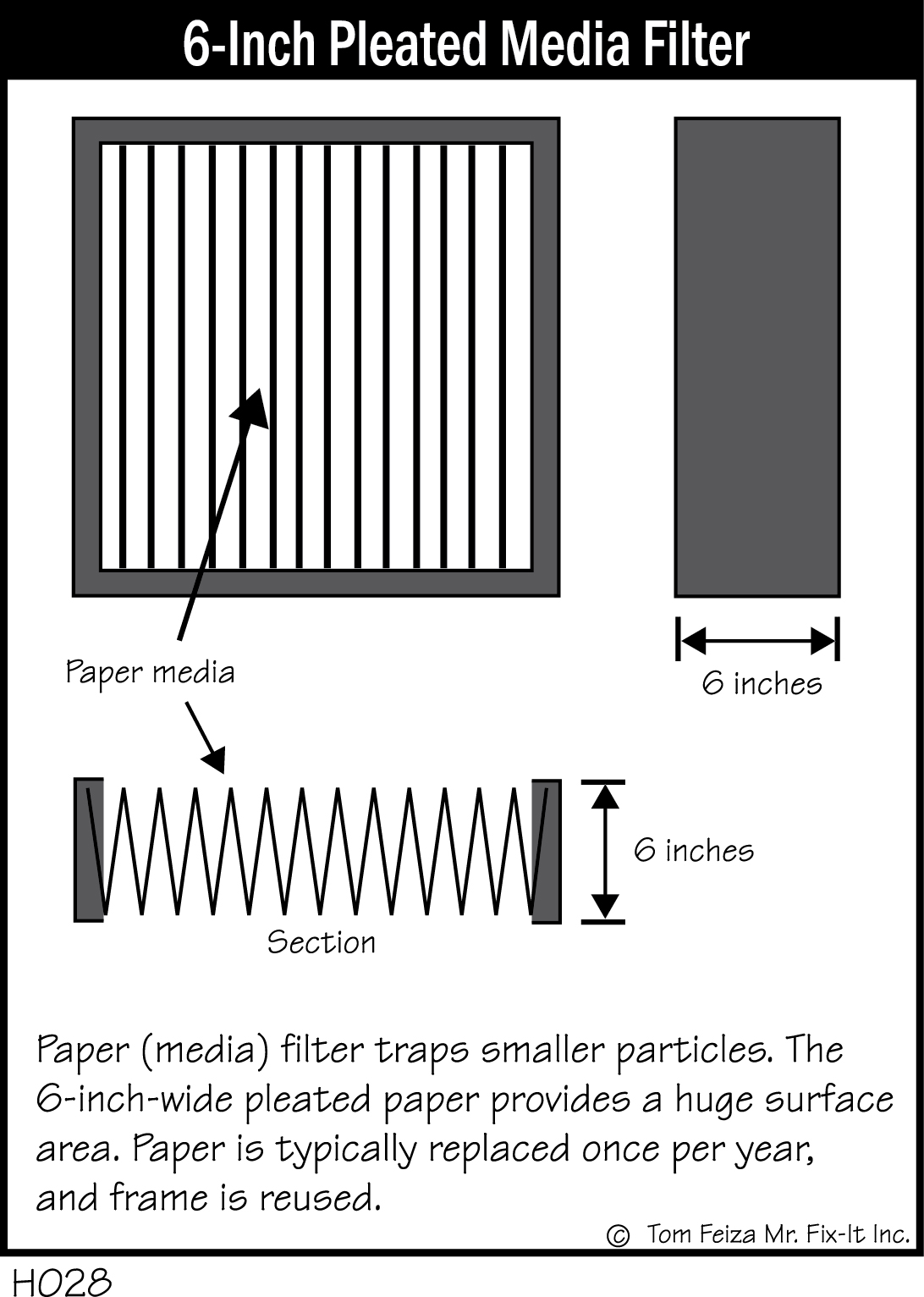

PLEATED, 4 TO 6-INCH THICK

A big improvement over the standard 1”-thick filter is a pleated fiberglass or paper filter.

Often, the pleated paper filter is housed in a 6”-thick frame. The paper filter is very fine, and it catches smaller particles of dirt and dust. This type of filter is normally changed once per year, and you replace only the paper element.

A pleated fiberglass filter often is mounted in a throwaway paper frame. The entire unit is replaced about once a year.

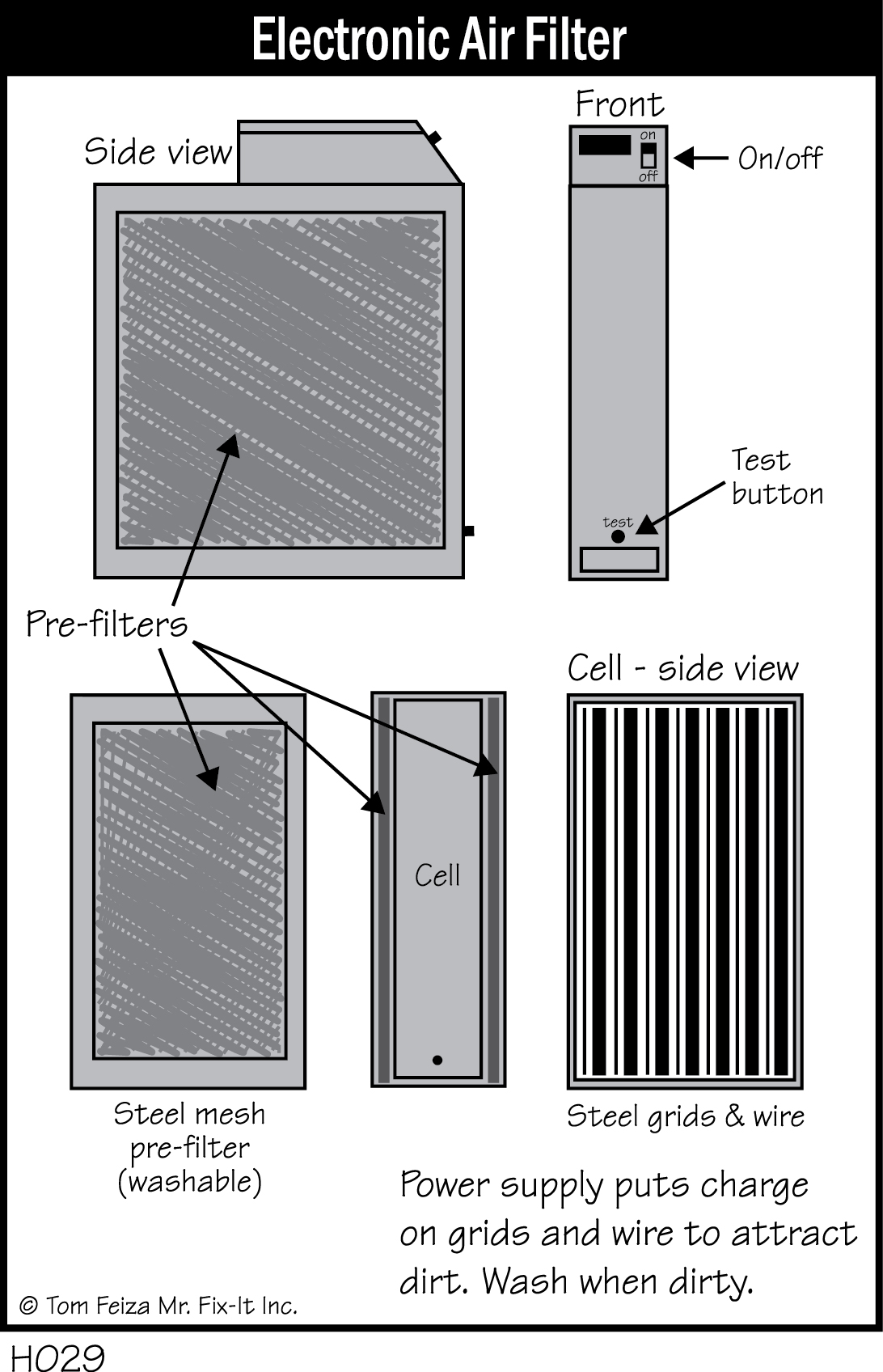

Electronic Filters

Electronic filters use electrically charged metal plates and wires that attract dirt. These filters can remove very small particles from smoke and pollen which aren’t caught by standard filters. If you have respiratory problems or are sensitive to dust or pollen, you may want to use this type of filter.

Electronic filters cost more than $600 to install. Maintenance involves washing the interior frame and metal plates and wires with detergent or running them through a dishwasher. Most electronic filters have a metal pre-filter that also must be washed. For more specific cleaning instructions, contact a heating contractor or the filter manufacturer.

Electrostatic and Electronic Filters

Many types of washable filters have multiple layers of filtering material; vendors claim these layers contain an electrostatic charge that attracts and traps dirt more effectively than a standard media filter.

Several companies also make a 1”-thick electrostatic/electronic filter as a direct replacement for throwaway filters. This filter may have an electronic power supply and may require particular maintenance procedures.

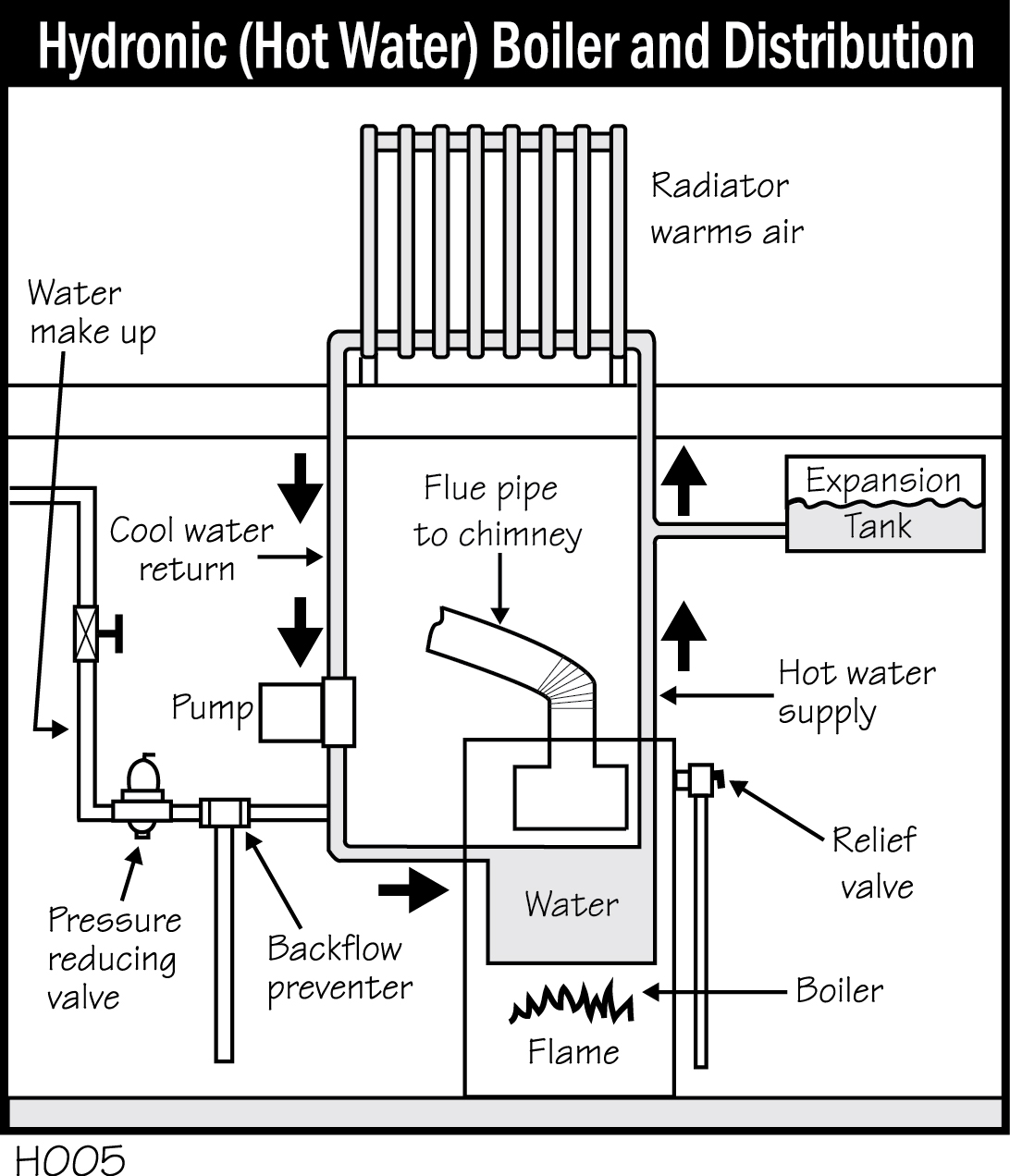

Hydronic (Hot Water) Heat

Hot water or hydronic systems provide heat by warming water and circulating it through piping to heating devices: radiators, baseboard convectors, radiant pipes in the floors or walls, or even coils with a fan. Older system typically use cast iron radiators; newer systems typically use baseboard convectors (finned tubes).

Hydronic systems usually burn oil, gas, or propane below a cast iron container or coil that holds water. The warmed water is then distributed to the radiators through a network of supply and return piping. Older systems use gravity to move the water—warm water rises, cool water falls. Newer systems use a small circulation pump to move the water.

The distribution system is sealed and should not leak, but water expands as it warms, so there will be an expansion tank to hold the increased volume. Most systems have an automated fill valve and backflow prevention.

The system automatically responds to a thermostat located in the heated space. When the thermostat calls for heat, the boiler and the pump start. Warm water is delivered to the radiators. When the thermostat is satisfied, the boiler is turned off.

There are many variations to hydronic systems: multiple zones provided by thermostat and zone control valves or multiple pumps…boiler temperature water resets based on outside temperature….many control options…and variations in piping systems, to name a few. If you have a complicated system, ask a service technician to explain it to you.

Hydronic Heating—Maintenance Requirements

All heating equipment should be routinely checked by a qualified service technician. Most hydronic boiler manufacturers recommend yearly maintenance to keep equipment operating efficiently and to ensure safety.

Contact the manufacturer of your furnace for specific maintenance requirements.

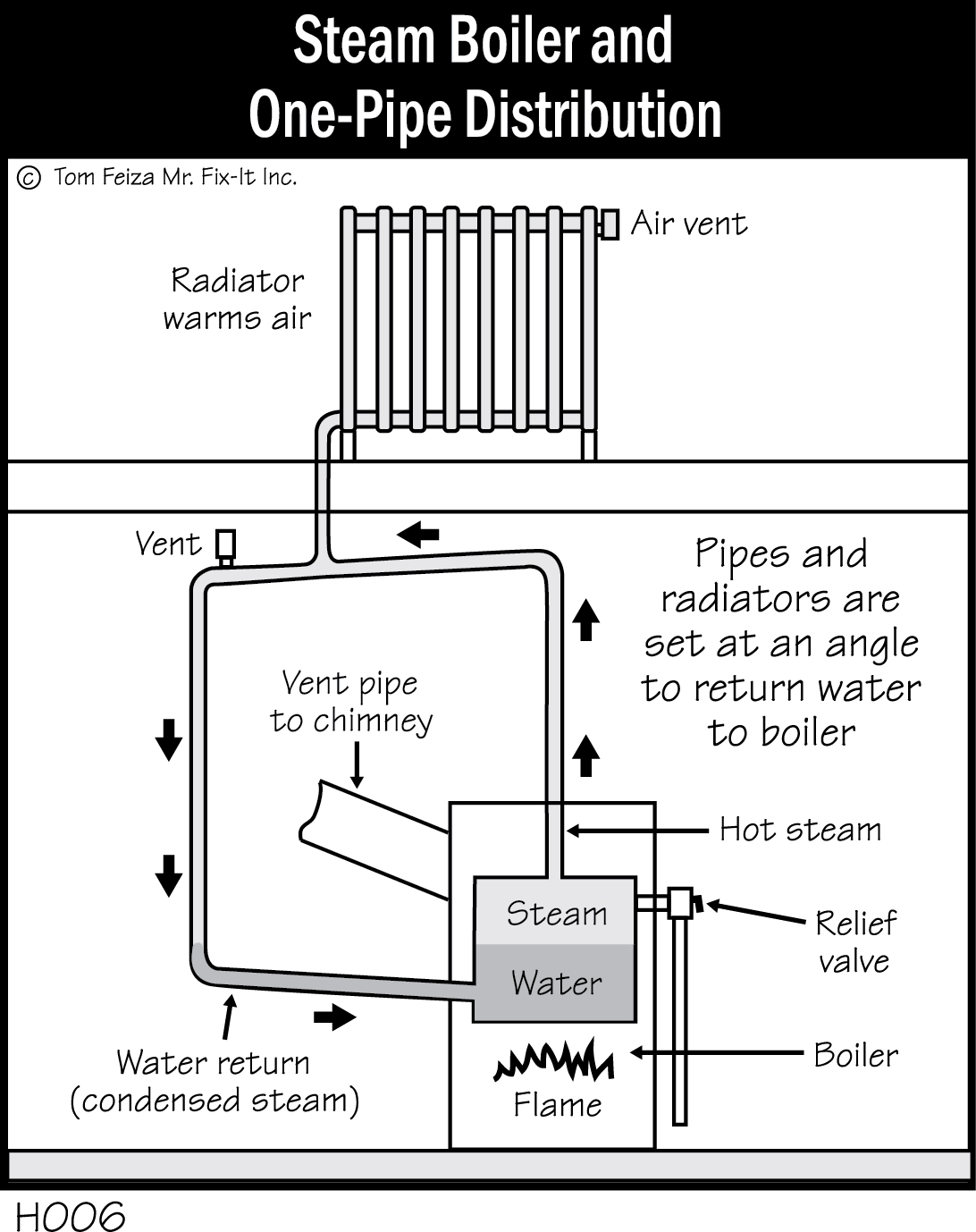

Steam Heating

A steam heating system is similar to a hydronic boiler system except that it produces steam at low pressure. Because they require more maintenance than hydronic systems, steam systems are rarely installed in newer homes, and older steam systems often are converted to hydronic systems.

Steam systems can use oil, natural gas or propane as an energy source. The burning fuel heats water in the boiler, turning it to steam. The steam, under pressure, rises through the system to the radiators. Vents in the radiators release heated air. The steam condenses back into water as it releases energy in the radiator, and the water flows back to the boiler to be reheated.

While there are variations in the piping systems, almost all residential systems are “one-pipe” systems as described above. You can identify a one-pipe system because it will have only one pipe connected to the radiators.

Steam systems should have professional maintenance at least once per year, perhaps more often. Much of the maintenance required by a steam system is too complicated for most homeowners to perform.

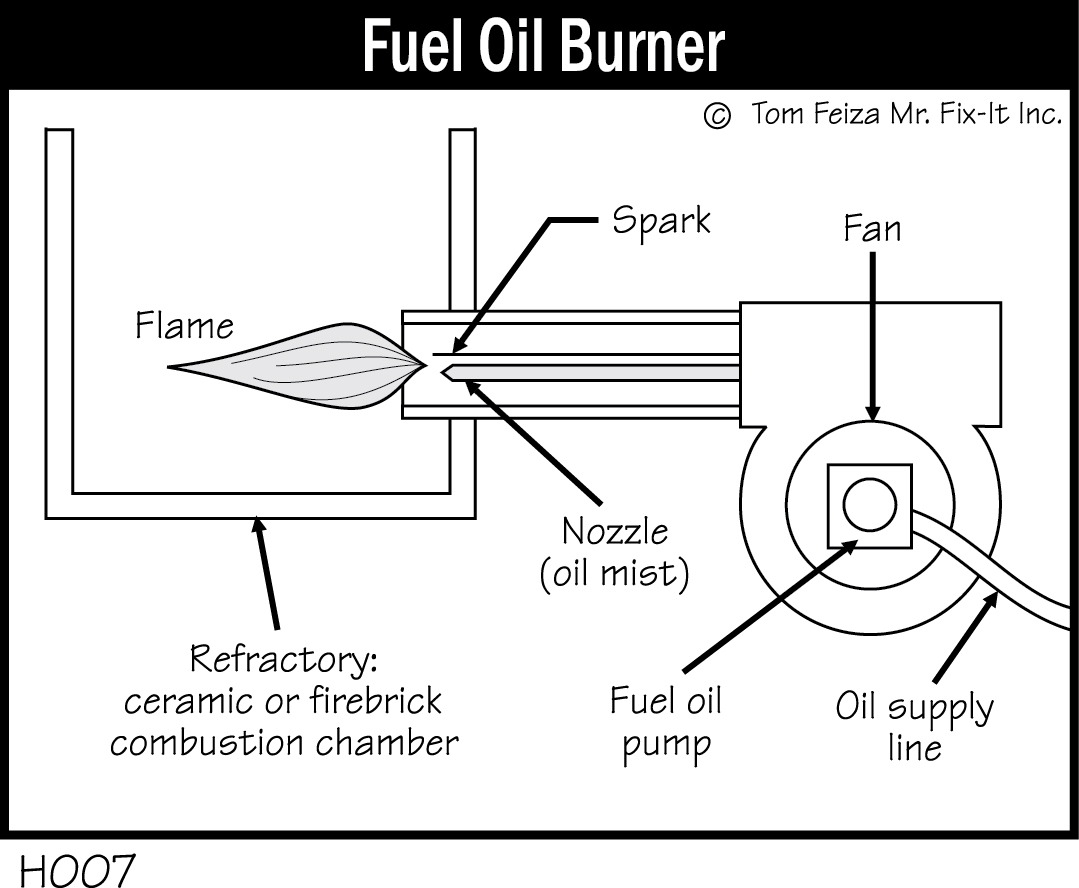

Oil Burner

An oil burner can be used just like a gas burner in warm air furnaces, hydronic systems or even water heaters. All oil burners are essentially the same except for some very old style vaporizing or pot-type burners. Here we will only cover modern pressure burners or gun-type burners.

A modern oil burner pressurizes oil and sprays it through a small nozzle, forming a mist. At the same time, the burner provides an air supply and a high-voltage spark. This results in a very hot flame that is contained in a ceramic combustion chamber. From the combustion chamber, the hot combustion gas flows up through the heat exchanger, just as in a gas-fired appliance.

Oil Heat—Maintenance Requirements

Oil burners can be quite efficient, comparable to gas units. Oil burners require yearly maintenance. Also, never let your oil system run out of fuel. This can cause major problems with the burner, requiring a service call.

Most homeowners find it convenient to arrange for an oil delivery and burner service company to provide automatic oil tank filling and yearly service. This is the best way to ensure that the system is operating properly. You will also be placed at the top of the service call list if you are an established customer.

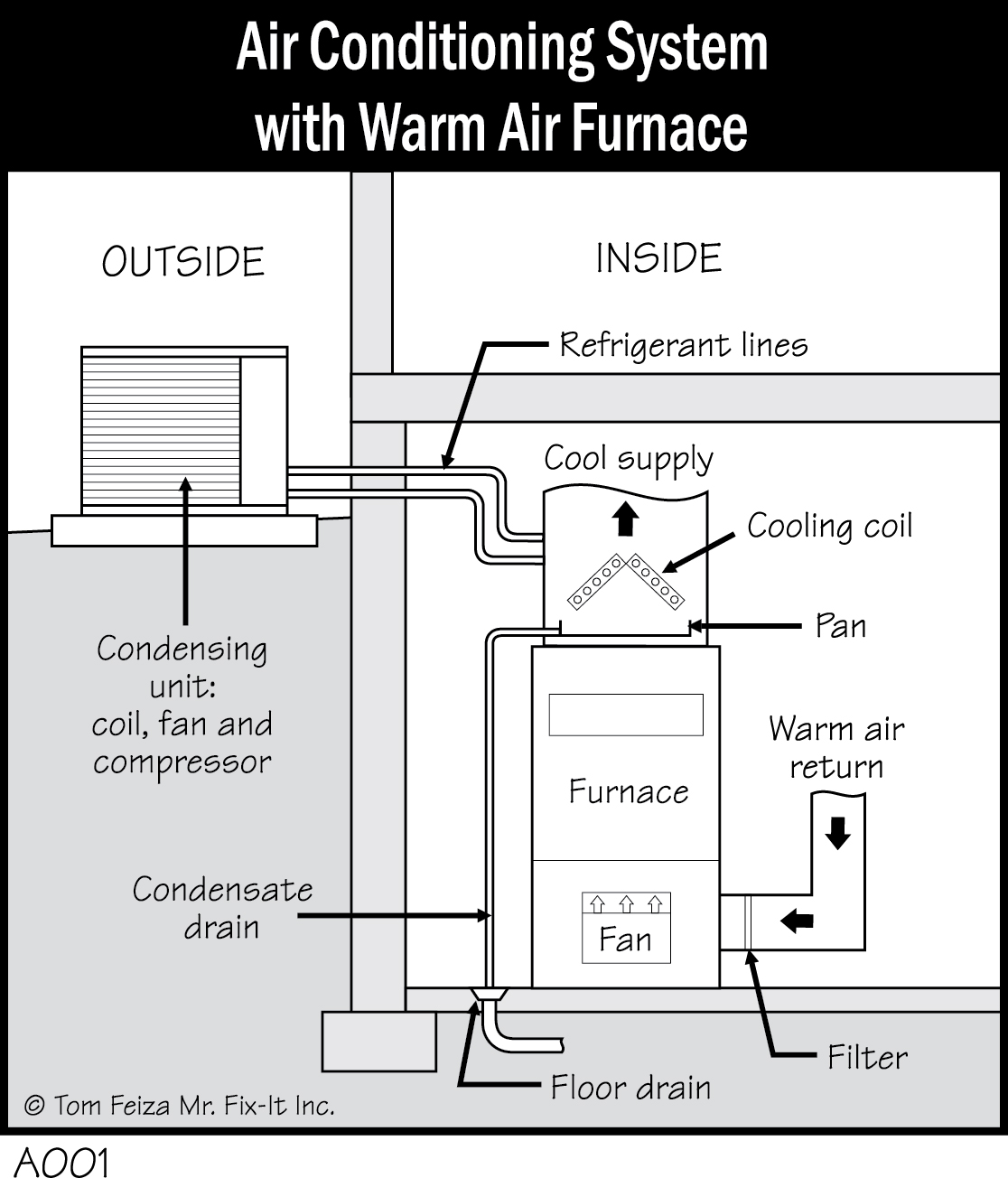

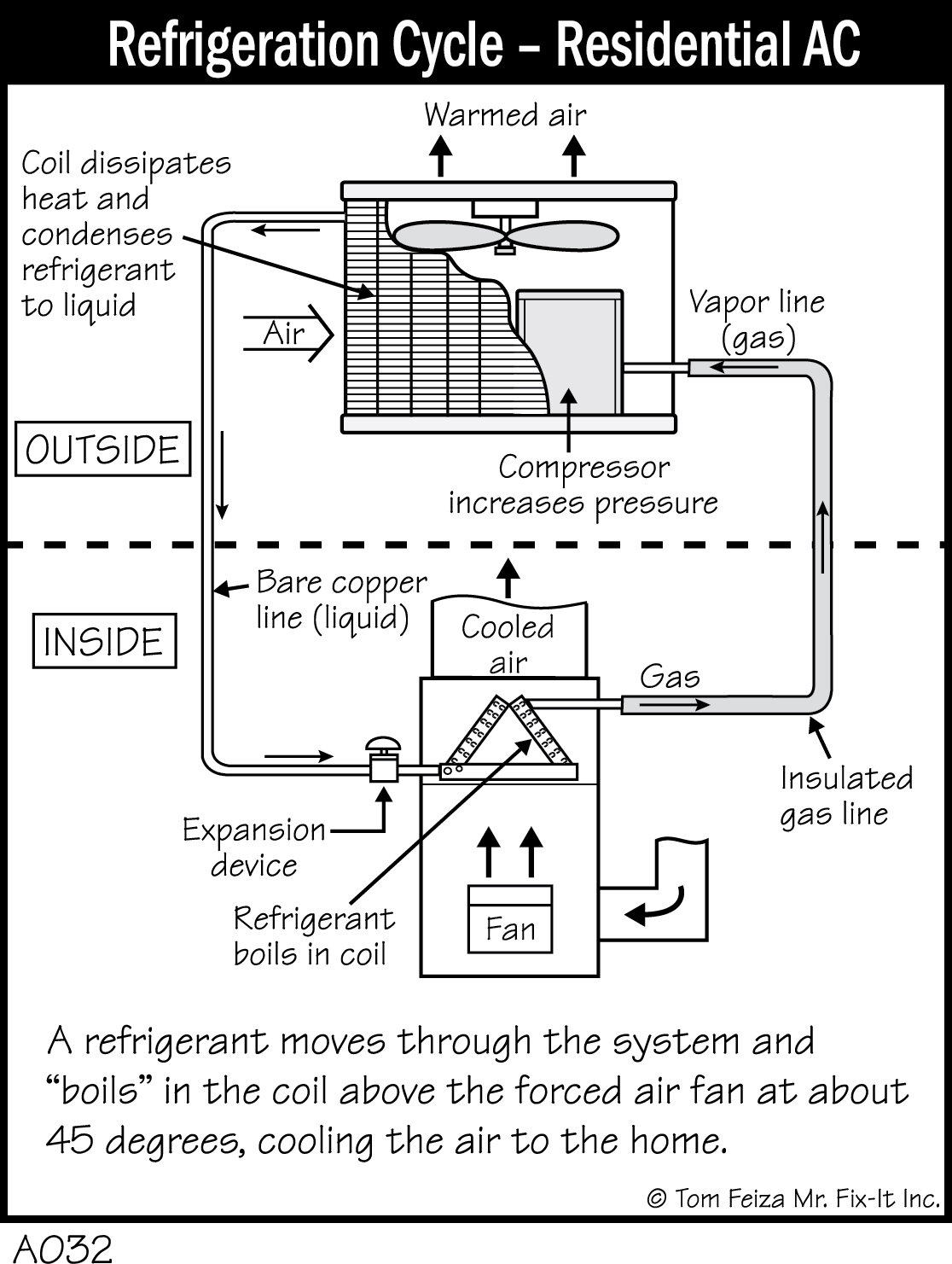

Central Air Conditioning

Central air conditioning uses a warm air furnace system to cool air and distribute it throughout the home. The air conditioning system uses the fan, filter, thermostat and ducts; the heating portion of the system remains turned off.

When a home has hydronic heat, central air conditioning may be provided by a separate system. In this case, there is no heating equipment in the standard furnace housing; it has only a fan and cooling coil.

A central air system includes an interior coil (in the furnace housing) that removes heat from the interior air and an exterior coil that rejects heat into air outside the house.

When the thermostat signals for cooling, this starts up the exterior refrigeration compressor, exterior fan and furnace fan. The exterior compressor moves refrigerant through the closed system of coils and valves to produce a cool coil inside.The furnace fan moves air across this coil. The air cools, and moisture condenses on the coil’s surface. This moisture is caught in a pan below the coil and drains away through a hose.

It is not necessary to cover the exterior unit during the winter, since these units are designed to withstand the weather. If you do cover the unit for some reason (for instance, if the unit is located where debris might accumulate on it), it’s best to cover only the top of the unit. If you were to securely wrap the sides, moisture could condense in the unit. Also, a wrapped unit provides a perfect winter home for animals that may chew wiring and cause other problems.

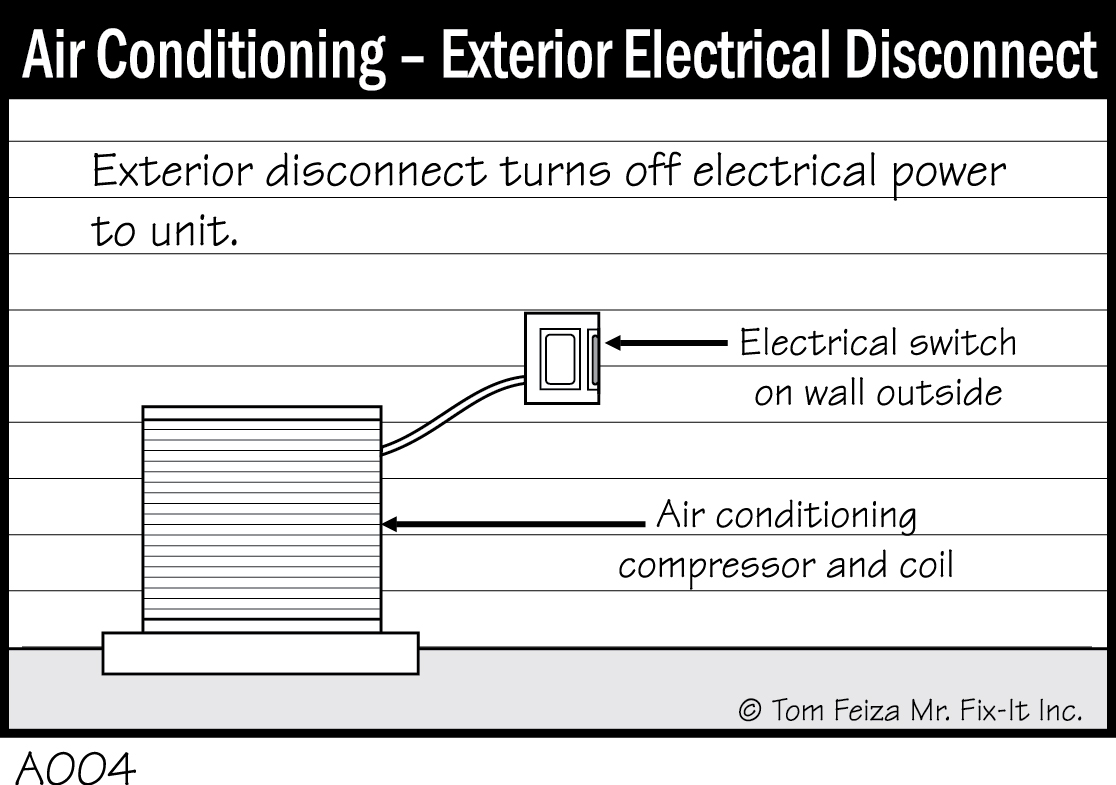

When it’s time for the winter shutdown, turn off power to the unit to prevent accidental operation. The power disconnect could be the breaker or fuse at the main panel. Or the disconnect may be at the exterior unit, usually as a switch or a fuse block or plug that you pull out to disconnect the power.

Central air conditioning systems should never be operated in cold weather. This can cause serious damage.

Don’t start the central air conditioner unless the outdoor temperature has been above 60 degrees for at least 24 hours. Remember to uncover the unit if you added a cover for the winter.

At the start of the cooling season, when you’re about to turn on power to the unit, make sure that the thermostat is switched off, and leave the thermostat off for 24 hours before operating the unit. If the unit has a crankcase heater, this procedure allows the heater to warm the unit.

Central Air Conditioning–Maintenance Requirements

Proper maintenance will keep the unit operating properly and save you energy costs. Have your air conditioning system checked yearly by a professional service contractor.

You should also perform basic maintenance. Contact the manufacturer of your furnace/AC unit for specific maintenance requirements.

Heat Pumps

A heat pump provides heating and cooling. Simply put, a heat pump is a central air conditioner that can cycle in reverse to provide heating.

Local conditions will dictate whether a heat pump is an efficient alternative for heating your home.

A heat pump transfers heat from an exterior coil to an interior coil in the warm air heating system. A heat pump provides efficient heating in areas where exterior temperatures are moderate. In cold winter weather, though, a heat pump is no more efficient than electrical resistance heating, which costs more to operate than a natural gas or oil furnace.

Before you use your heat pump, have a professional explain its operation. Unfortunately, it’s easy to accidentally operate the system with emergency electrical heat; in this mode, the heat pump is turned off and electrical resistance heating coils turn on. This method works fine, and you may not observe any problems—until you get your electric bill.

The emergency (electrical resistance) system should only be used when (1) the heat pump is not working, or (2) the outside temperature is so cold (about 30 degrees or lower) that the heat pump would be less efficient than electric resistance heating. When the outside temperature gets this low, emergency resistance heating turns on automatically. You do not need to adjust the controls.

Heat Pump—Maintenance Requirements

Maintenance for a heat pump is similar to that for central air conditioning systems, but because a heat pump is operated winter and summer, it will require more maintenance.

Humidifier Controls and Settings

In northern heating climates, homes can become very dry in the winter. As warm air leaks out of our homes, it is replaced with cold, dry air. This is less severe if we have tightened up our homes for energy conservation, but it still can be a problem. Excessive dryness can damage furniture and harm your physical well-being.

The simple way to add moisture to the air of your home is with a central humidifier on your warm air furnace. A modern system is easy to maintain and should not leak. Modern systems have automatic controls that sense humidity level and operate automatically.

Older systems are not the best, but some are serviceable. Do not use the type that employs a water pan with an automatic fill valve. These are hard to maintain, may harbor disease-causing bacteria, and can leak water and ruin a furnace by rusting it out.

The type with a water panel and drain (Aprilaire is a common brand) works well if you maintain it. This system slowly flushes water across a perforated metal panel, where the air picks up moisture. Excessive water drains through a pan and hose. In general, maintenance requires changing the water panel yearly and cleaning the pan and drain lines. Routinely check for water leaks, and keep the drain line clear.

You must also adjust the humidistat to compensate for the outside air temperature. The humidistat looks like a thermostat and is located next to the thermostat or on the ductwork of the furnace. The colder the outside temperature, the lower the interior humidity level should be. Your windows provide a great humidity indicator. If moisture condenses on the windows, the interior humidity level is too high.

Aprilaire offers a humidistat that automatically compensates for outside air temperature.